- Joined

- Apr 21, 2013

- Messages

- 208

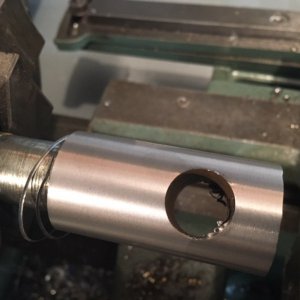

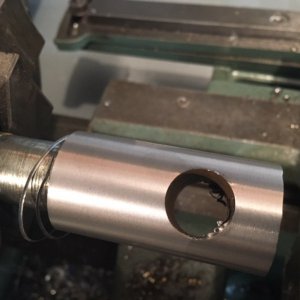

I picked up a Wilton 1765 Tradesman vise that was being junked by a local business. The jaws were destroyed and the main spindle in the retainer clip area had massive wear, as did the clip itself. Otherwise, it was in good condition. I ordered a clip and the jaws, which was easy. To repair the spindle, I was first going to weld it in and turn it down, but a friend recommended that I turn it down and sleeve it, which is what I did. The sleeve had a 5/16" wall (the groove is 1/8" deep). I made the sleeve slightly longer than the area on the spindle and then welded in the ends. After turning on my lathe, it came out great. The handle also needed replaced, so I turned a rod down to .700 for that, with 1/2" shoulders on each end. I turned the handle ends with a radius HSS bit I had, inverting the bit and reversing the lathe for the back side. I wish I had a before photo of the whole vise, but I only had the photo of the spindle wear.

I used Rustoleum hammered blue to paint the vise.

P.S. The company that abused the vise used it for weld failure analysis. According the number on the slide, the vise was built in 2002.

I used Rustoleum hammered blue to paint the vise.

P.S. The company that abused the vise used it for weld failure analysis. According the number on the slide, the vise was built in 2002.