- Joined

- Dec 17, 2012

- Messages

- 630

Looking good. What are you doing for threading the large threads for the collet holder?

Looking good. What are you doing for threading the large threads for the collet holder?

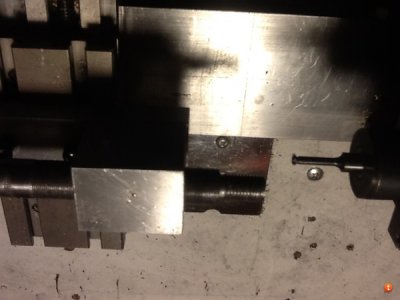

I use a bolt in tailstock, with correct threads. A hole is drilled and tapped in the work piece to match that. Threading is then done by turning the spindle by hand.

A bit tedious but this method is used by many lathe owners, some smaller than Taig, e.g. Unimats. Great for those cases where you don't have a lead screw/gear cutting gear set.

One of the photos shows the set up from above.

Gerrit