- Joined

- Apr 30, 2012

- Messages

- 2,401

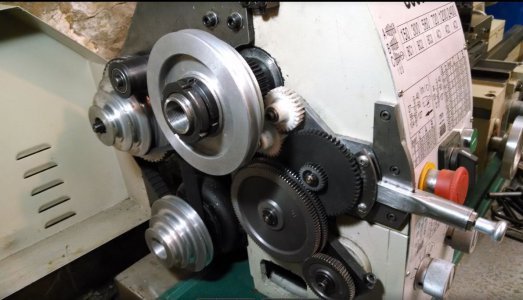

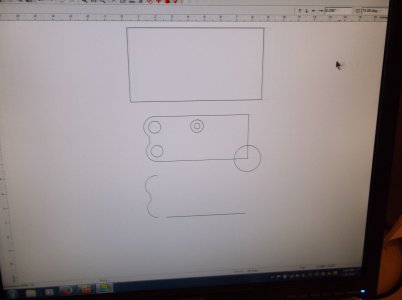

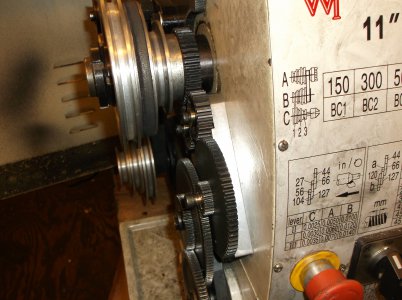

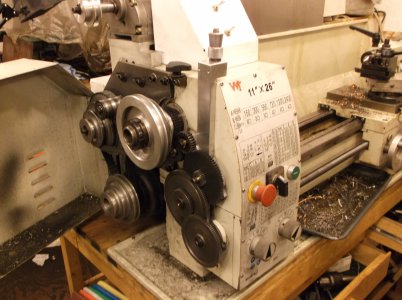

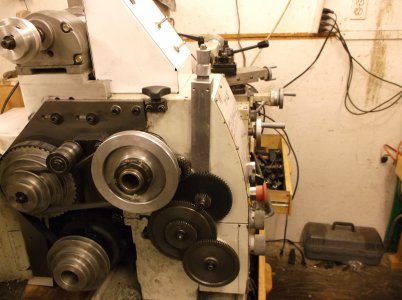

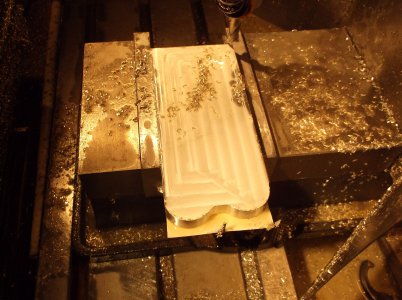

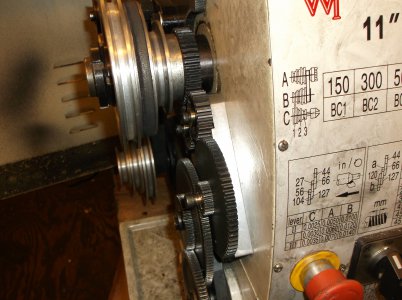

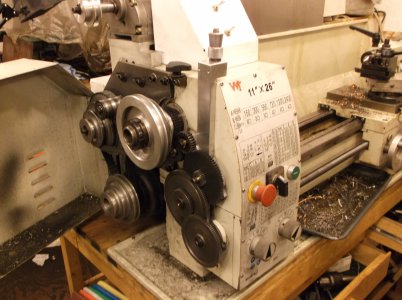

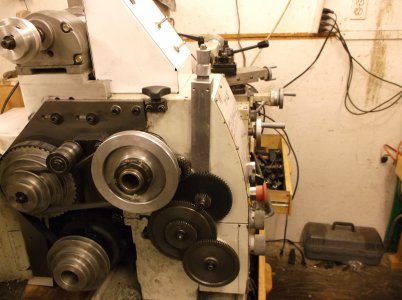

Today I completed my reverse tumbler modification on my 11 x 26 Wholesale Tools lathe. This mod will also fit the Grizzly g0602 10 x 22 lathe.

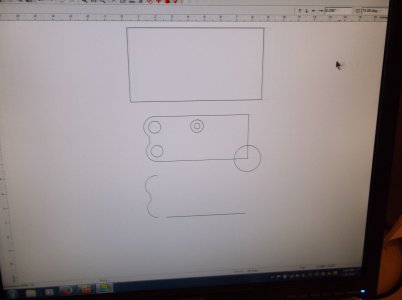

It has bugged me since i purchase the lathe that there was not a neutral position or the possibility of turning left hand threads. After doing research online I found out that the gears I needed were m1.5 module and 20 degree pressure angle these also were the same gears used in a Briggs and Statton side shaft 5hp engine ( Thanks to a really good write up at Projectsinmetal.com by Norman Leonard. http://www.projectsinmetal.com/forum/general-discussion/reverse-for-g0602/ )

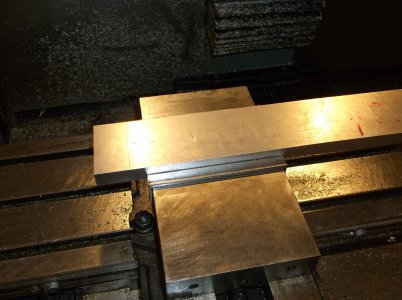

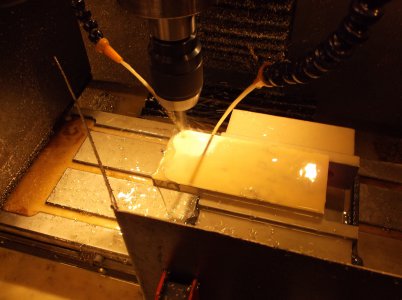

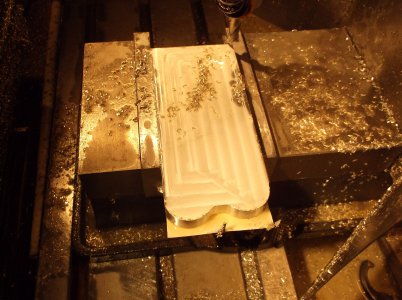

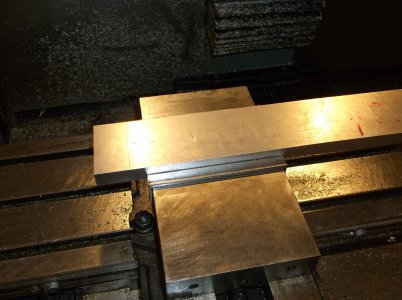

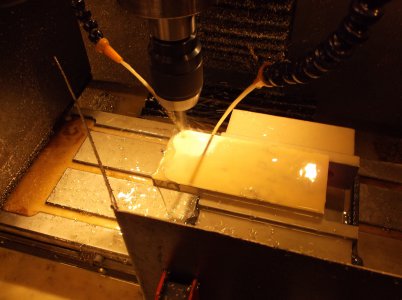

My design is different but the article really helped, I purchased 4 new gears for $20 and a tube ( 10 ) of 6000-2rs bearings for $10 on ebay. the Locking handle is off a 9x20 lathe everything else I made here in my shop.

Steve

It has bugged me since i purchase the lathe that there was not a neutral position or the possibility of turning left hand threads. After doing research online I found out that the gears I needed were m1.5 module and 20 degree pressure angle these also were the same gears used in a Briggs and Statton side shaft 5hp engine ( Thanks to a really good write up at Projectsinmetal.com by Norman Leonard. http://www.projectsinmetal.com/forum/general-discussion/reverse-for-g0602/ )

My design is different but the article really helped, I purchased 4 new gears for $20 and a tube ( 10 ) of 6000-2rs bearings for $10 on ebay. the Locking handle is off a 9x20 lathe everything else I made here in my shop.

Steve

Last edited: