- Joined

- Aug 9, 2011

- Messages

- 67

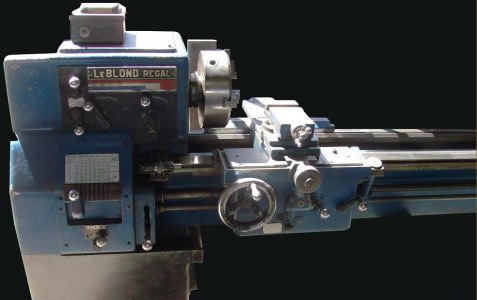

Well after looking for so long and getting the #11B&S to MT2 sleeve I went to install it and look what I found. I am kicking myself in the head for not looking at the inside earlier. Live and learn. just never expected anyone would do such a thing.

Once again back to the main rule of life. ASSUME NOTHING! This was something that I didn't expect to assume though.

I can't afford this crap on my new machine.

So if anyone wants these sleeves and I think is a #11 taper solid bar let me know. $25 for both plus flat rate shipping.

Once again back to the main rule of life. ASSUME NOTHING! This was something that I didn't expect to assume though.

I can't afford this crap on my new machine.

So if anyone wants these sleeves and I think is a #11 taper solid bar let me know. $25 for both plus flat rate shipping.