- Joined

- Apr 6, 2011

- Messages

- 2,082

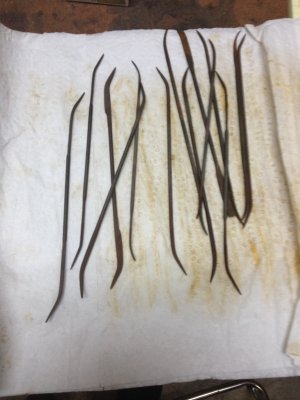

I've been meaning to try Evaporust, heard great things about it, even saw it at HF a while back. Do parts have to be submerged to work, like can it be used as a spot remover for rust for parts that are too large to submerge? I'm assuming the reason is cause it needs plenty of time to work.

I've been using gun blue remover for parts to big to submerge. I also have a bottle naval jelly but I've never tried it yet.

Saw on TV recently they now have a bucket (2.5 gal?) that comes with a strainer to holds parts. Been thinking about getting it.

For "spotting" and parts too large to submerge I would probably to with the naval jelly. You can spot with the evapo-rust using soaked (and keeping them soaked) paper towels or running it across the part with a small fountain pump but I think the gel would be less mess and hassle.

Definitely get some and try it out though, amazing stuff.

JMHO,

-Ron