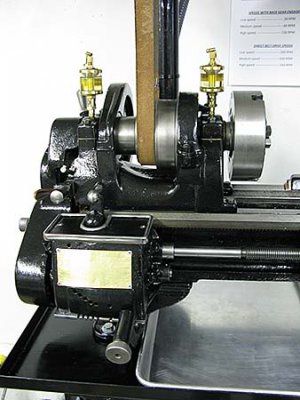

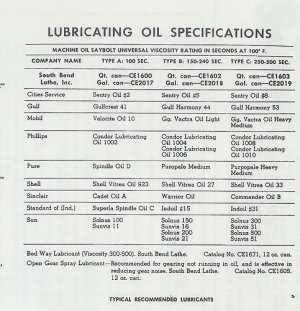

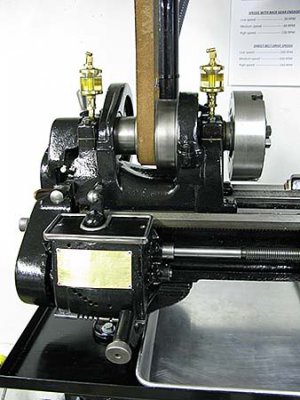

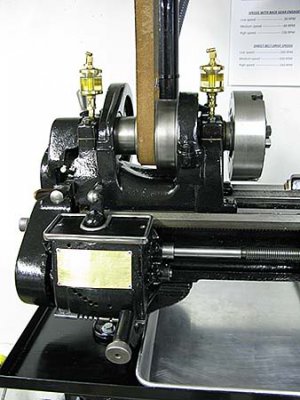

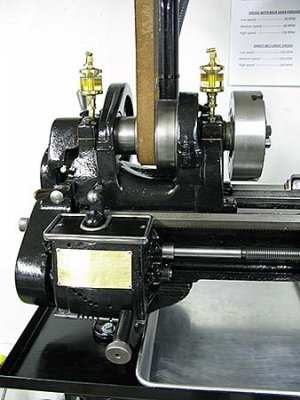

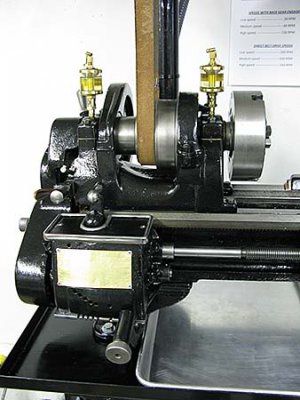

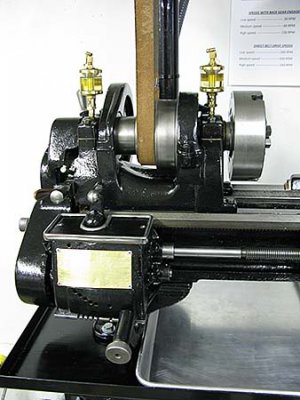

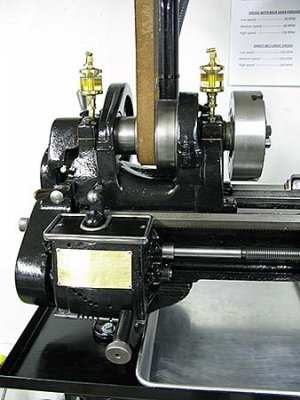

I have been using Velocite #6 on the bronze spindle bearings of my 1930 Model O series heavy 9. Should I be using the heavier #10. I have had no problems with #6, but I have noticed it is quite thin and does run thru the lathe headstock rather quickly, but it's not that bad! Never had even warm bearing temps with #6. Brass oilers lubricate the spindle bearings.

Regards.

Skipd1

Regards.

Skipd1