Hi Guys

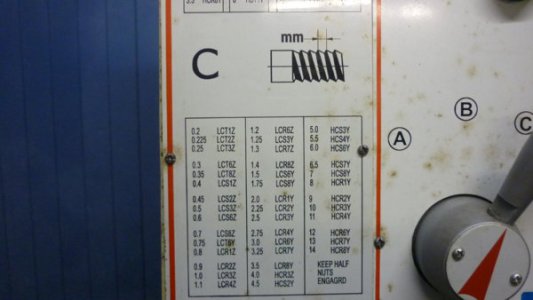

Need courage to ask this. ( Obvious Answer to many) Has to be asked though, from what I am presently using as LCT1Z

What setting on my lathe would I use to achieve the slowest Finest Feed for Finish Turning.

Have attached a pic of the Face of the Lathe with the various Screw Settings

TIA

ATB and LORD Bless.

aRM

Need courage to ask this. ( Obvious Answer to many) Has to be asked though, from what I am presently using as LCT1Z

What setting on my lathe would I use to achieve the slowest Finest Feed for Finish Turning.

Have attached a pic of the Face of the Lathe with the various Screw Settings

TIA

ATB and LORD Bless.

aRM