- Joined

- May 7, 2014

- Messages

- 776

Gang, I'm sitting w/ my Son and we're banging away hour after hour trying to setup Mach3 and our Mill. Sorry in advance for all the Q's but we are trying hard here. It's purchased used (yeah, I know I know). But I am OK w/ sweat equity and solving others mistakes. And there have been some doozies.

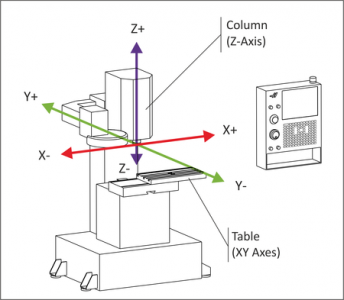

Where is a Mill tables Machine Home (000) supposed to be? I'm trying to load and tell Mach the home based on the switches as follows:

FROM THE FRONT OF THE MACHINE . Standing facing it.

X is to the far Right. (run length of 14.2")

Y has the table coming back at you to hit the limit switch (run length of 11.5")

Thanks

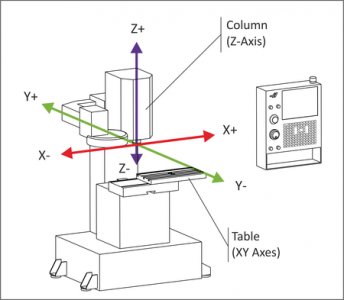

Where is a Mill tables Machine Home (000) supposed to be? I'm trying to load and tell Mach the home based on the switches as follows:

FROM THE FRONT OF THE MACHINE . Standing facing it.

X is to the far Right. (run length of 14.2")

Y has the table coming back at you to hit the limit switch (run length of 11.5")

Thanks

Last edited: