Hi all,

I'm working on restoring a 10" rotary table for use on my Gorton 8-1/2D vertical mill. It's almost there - one of the last things to do is make up a table lock clamp. This afternoon, I cobbled something together as a proof of concept, but it doesn't work as well as I'd hoped.

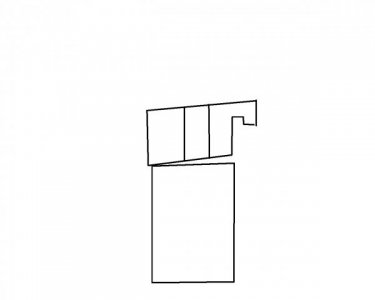

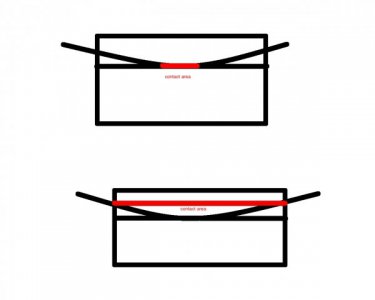

The clamp engages the slot around the periphery of the table, and tightening the 5/8 nut *should* clamp the front down hard. The heel of the clamp is sitting on a shim which raises it slightly higher than the front, similar to how milling hold-downs work. There's sufficient gap under the clamp for the nut to be tightened completely without interference.

With all that said, I'm able to tighten the nut down fully as expected. But, I'm still able to turn the handwheel and make the table turn. It's a good bit harder than when the clamp is not tightened, but it's still mobile.

Is this expected, as a result of the 40:1 gearing? i.e. the clamp will be sufficient to withstand milling forces, even though the worm can still turn the table? Or is something wrong with my design?

Thanks in advance for any advice,

Lee

Sent from my SM-N920T using Tapatalk

I'm working on restoring a 10" rotary table for use on my Gorton 8-1/2D vertical mill. It's almost there - one of the last things to do is make up a table lock clamp. This afternoon, I cobbled something together as a proof of concept, but it doesn't work as well as I'd hoped.

The clamp engages the slot around the periphery of the table, and tightening the 5/8 nut *should* clamp the front down hard. The heel of the clamp is sitting on a shim which raises it slightly higher than the front, similar to how milling hold-downs work. There's sufficient gap under the clamp for the nut to be tightened completely without interference.

With all that said, I'm able to tighten the nut down fully as expected. But, I'm still able to turn the handwheel and make the table turn. It's a good bit harder than when the clamp is not tightened, but it's still mobile.

Is this expected, as a result of the 40:1 gearing? i.e. the clamp will be sufficient to withstand milling forces, even though the worm can still turn the table? Or is something wrong with my design?

Thanks in advance for any advice,

Lee

Sent from my SM-N920T using Tapatalk