- Joined

- Jun 24, 2015

- Messages

- 44

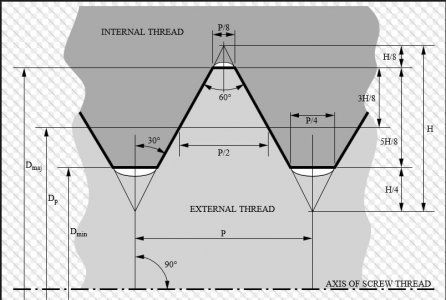

I want to buy a threading tool holder and insert to do some 1/4"-20 or maybe 1/4"-28 single point threading. There are so many different inserts I don't know what to get. UN thread type or partial 60*? Is there an advantage to one vs the other? It looks like the UN inserts are thread pitch specific whereas the partial are more universal.

The lathe I will be using is a 12x36 Pratt&Whitney with a QC tool holder that looks like it will take a 3/4" sq shank. I was going to buy a 1/2" though as that is what is being used in the machine. I don't know if 3/4" puts the insert above centerline or what. The material will be 4130.

The lathe I will be using is a 12x36 Pratt&Whitney with a QC tool holder that looks like it will take a 3/4" sq shank. I was going to buy a 1/2" though as that is what is being used in the machine. I don't know if 3/4" puts the insert above centerline or what. The material will be 4130.