-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What rotary table to get

- Thread starter schor

- Start date

- Joined

- Nov 16, 2012

- Messages

- 5,596

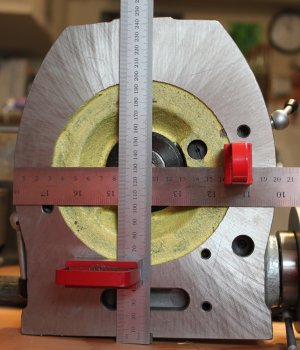

I've got a benchtop mill and would like to get a rotary table for it. The milling table is 5.125x19.5.

I can get a 3", 4" and 6" rotary table for a reasonable price, what should I go for? Will a 6" be too big?

Depends... For the sake of convenience, it's nice to have a unit where the bolt holes line-up with the slots in the table. If you can get that information, it's worth taking into consideration.

Ray

Grizzly has a 6" with dividing plates and a tailstock for a very reasonable price. You can easily spend the same money on a Chinese 6" without these goodies. I think the fit and finish are pretty nice for Chinese too.

B

Bill Gruby

Forum Guest

Register Today

IMHO -- This is as good as it gets for the money. This is the one I own.

Grizzly -- H7527 -- 6" Rotary Table W/Dividing Plates and Tail Stock.

"Billy G"

I can blow holes in the theory that you can't do big work on a small machine 24/7. I have disproved the theory many times over.

Grizzly -- H7527 -- 6" Rotary Table W/Dividing Plates and Tail Stock.

"Billy G"

I can blow holes in the theory that you can't do big work on a small machine 24/7. I have disproved the theory many times over.

- Joined

- Jun 11, 2013

- Messages

- 731

So that Grizzley looks much the same as this from busybee here in Canada.

http://www.busybeetools.com/products/ROTARY-TABLE-6IN.-C{47}W-TAIL-STOCK{47}INDEXING.html

Hopefully it won't be too big for my machine.

http://www.busybeetools.com/products/ROTARY-TABLE-6IN.-C{47}W-TAIL-STOCK{47}INDEXING.html

Hopefully it won't be too big for my machine.

B

Bill Gruby

Forum Guest

Register Today

Yup, same thing. Price id close to.

"Billy G"

"Billy G"

I have a small 4" i used with my first mill (LMS bench mill). It worked fine, the knob could hit the scales, so had to be careful. I have a 12" h/v for the mill, that is too heavy to either put onto the table... or take off, so it gets little use. I think a 6" would be great even for a knee mill.

- Joined

- Nov 3, 2013

- Messages

- 405

I have a small 4" i used with my first mill (LMS bench mill). It worked fine, the knob could hit the scales, so had to be careful. I have a 12" h/v for the mill, that is too heavy to either put onto the table... or take off, so it gets little use. I think a 6" would be great even for a knee mill.

Dang, I just got a 200+ pound cross slide RT and I plan to transfer it between my two Gorton mills as required.

Thankfully I can still handle moving 200 pounds.

I like heavy, both in my machine tools and in my accessories.

- Joined

- Nov 2, 2012

- Messages

- 415