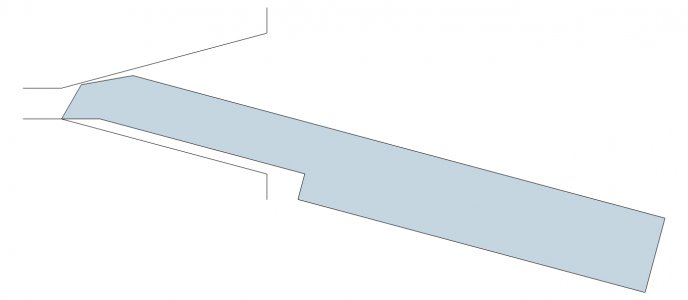

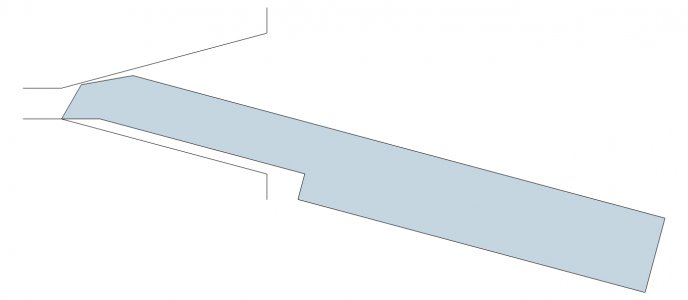

If it is easier on you, you can use a RH turning tool. You asked about 3/8 HSS blank. Set the tool a couple of thousands high and round off the bottom to get extra clearance. As stated the bit doesn't know what it is cutting. Drill a hole in the center, 1/8" You do your compound setup at 15 degrees. Turn the tool into the work another degree or so and and go for it. When you get to the bottom on the last cuts, narrow the right side and the bottom as needed for clearance. Look at Mickri's picture. You will have a straight bottom side and the top side will be even narrower. You can take fine cuts with a RH tool that is only 1/8" wide. After it is done, you will have a very narrow RH turning tool. Buy doing it this way you can cut the funnel up to the length of stick-out from the holder. I have done tapers before with this method and with the boring bar and both work.

I'm making a HSS boring bar real soon to make .170 holes in wood about 3/4" long for Clarinet tone holes. It will look like Mickri's picture.