- Joined

- Feb 2, 2013

- Messages

- 3,622

Mission:

retrofit control system, remove unnecessary components, bring machine back from DEAD!

make machine operate ASAP ! (wanted it yesterday)

Before:

disassembled...

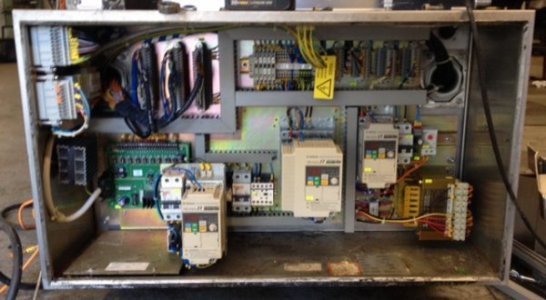

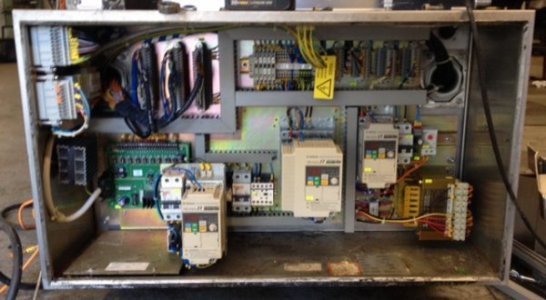

after control retrofit:

yes, there are a million wires present....

i have had bowls of spaghetti that have looked tamer!

shortened infeed system:

and the side view:

retrofit control system, remove unnecessary components, bring machine back from DEAD!

make machine operate ASAP ! (wanted it yesterday)

Before:

disassembled...

after control retrofit:

yes, there are a million wires present....

i have had bowls of spaghetti that have looked tamer!

shortened infeed system:

and the side view:

Last edited: