- Joined

- Aug 16, 2016

- Messages

- 193

Hey folks,

Been away for a while unfortunately. I had a lot of house stuff going on and my usual back issues bogging me down. Hope everyone is well and the machines are turning.

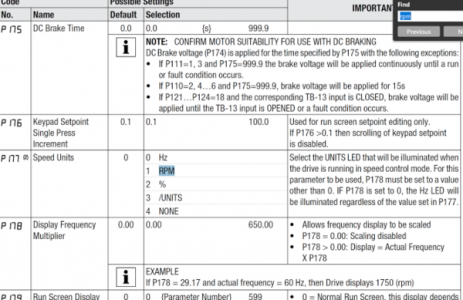

Last time I was on here I was getting ready to set up the Lenze VFD on my Series I. Well needless to say that still needs to be completed. But, I did compile and print out all of the information such as the relevant posts on this site and my notated manual. I put it all in a 1/2" 3-ring binder making it all very pretty. At least it will be until I put greasy fingers on the page corners.

I have been picking up a few end mills here and there for my personal gunsmithing adventures on the mill. Any home gunsmiths around? Speaking of that, I am a Pacific Tool & Gauge customer and there is a document on their web site which I found interesting. The file name is 'Feeds and Speeds" but it talks about 'Reamer/ Cutting Fluid Recommendations' and I have attached it here. As per the recommendation I bought some ATF transmission fluid and some Chevron cutting oil. Hopefully I will have the VFD setup soon and get to use the fluid.

Take care,

Been away for a while unfortunately. I had a lot of house stuff going on and my usual back issues bogging me down. Hope everyone is well and the machines are turning.

Last time I was on here I was getting ready to set up the Lenze VFD on my Series I. Well needless to say that still needs to be completed. But, I did compile and print out all of the information such as the relevant posts on this site and my notated manual. I put it all in a 1/2" 3-ring binder making it all very pretty. At least it will be until I put greasy fingers on the page corners.

I have been picking up a few end mills here and there for my personal gunsmithing adventures on the mill. Any home gunsmiths around? Speaking of that, I am a Pacific Tool & Gauge customer and there is a document on their web site which I found interesting. The file name is 'Feeds and Speeds" but it talks about 'Reamer/ Cutting Fluid Recommendations' and I have attached it here. As per the recommendation I bought some ATF transmission fluid and some Chevron cutting oil. Hopefully I will have the VFD setup soon and get to use the fluid.

Take care,