-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

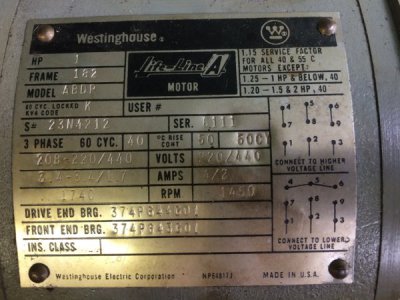

Westinghouse 1 Hp Grease

- Thread starter Al 1

- Start date

- Joined

- Jun 22, 2012

- Messages

- 1,552

As far as I know most electric motors, especially vintage ones take oil not grease.

- Joined

- Feb 2, 2013

- Messages

- 3,625

as mentioned above, vintage/antique motors used mostly oil for lubrication

the motor you have shown is modern enough to have had grease packed in the bearings, hence the end grease cap .

you can safely use a lithium soap or a lithium complex grease in your motor.

many manufacturers make the greases- Sta-Lube, Mobil, Shell, Phillips, Super-Tech (a Walmart brand), Traveller (a Tractor Supply Co. brand), Kendall, Valvoline, etc

lithium complex greases can take higher pressures and heat than the soap counterpart, but both would be acceptable regardless.

another thing to remember, you do not want to overfill a bearing, doing so will adversely affect the operation and longevity of the bearing.

there is a formula for the filling of a bearing believe it or not:

G = 0.114 x D x B

G= grease (in ounces)

D= bore diameter (in inches)

B=bearing width (in inches)

the motor you have shown is modern enough to have had grease packed in the bearings, hence the end grease cap .

you can safely use a lithium soap or a lithium complex grease in your motor.

many manufacturers make the greases- Sta-Lube, Mobil, Shell, Phillips, Super-Tech (a Walmart brand), Traveller (a Tractor Supply Co. brand), Kendall, Valvoline, etc

lithium complex greases can take higher pressures and heat than the soap counterpart, but both would be acceptable regardless.

another thing to remember, you do not want to overfill a bearing, doing so will adversely affect the operation and longevity of the bearing.

there is a formula for the filling of a bearing believe it or not:

G = 0.114 x D x B

G= grease (in ounces)

D= bore diameter (in inches)

B=bearing width (in inches)

Frank is on tract, take the bottom plug out, run the motor until warm, I have read about two different ways to grease the bearings, 1) fill the top opening with grease until it forces the old grease out the bottom. Leave the bottom open and run to allow any extra grease to leak out, or 2 Open the bottom drain plug, just put "some" grease in the top opening, run the motor with bottom open to allow any excess grease to drain. Clean up any mess, replace the plug and your done

I found a maintenance manual for GE motors, it said to regrease the motor every 10 years. I found a Westinghouse manual, use POLYUREA grease and regrease every 7 years.

see page 8 for lubrication

http://www.tecowestinghouse.com/manuals/TWMC Instruction Manual_143 to 449 frame.pdf

Ulma Doctor was posting while I was typing, I'd go with his formula for the correct amount of grease

I found a maintenance manual for GE motors, it said to regrease the motor every 10 years. I found a Westinghouse manual, use POLYUREA grease and regrease every 7 years.

see page 8 for lubrication

http://www.tecowestinghouse.com/manuals/TWMC Instruction Manual_143 to 449 frame.pdf

Ulma Doctor was posting while I was typing, I'd go with his formula for the correct amount of grease

- Joined

- Jun 22, 2012

- Messages

- 1,552

Well I learned something here too! I did nut know that some motors take grease. How could I not know that? Just seems like all the motors I have ever had took oil, lol.

- Joined

- Feb 2, 2013

- Messages

- 3,625

a lot of the old motors used bushings made of babbitt, bronze, or oilite bushings and were (relatively) low speed motors.Well I learned something here too! I did nut know that some motors take grease. How could I not know that? Just seems like all the motors I have ever had took oil, lol.

all these bearing(bushing) materials function well with oil as the lubricant.

when the motor speeds started going up, the manufacturers started using roller bearings in the motors for both efficiency and longevity at greater speeds.

generally speaking, typical electric motors use roller bearing construction now- but most are lifetime (of the bearing) lubricated- without provision for external lubrication.

nowadays the better manufacturers will have grease zerks to pump up

- Joined

- Nov 2, 2013

- Messages

- 960

If you can't find the Polyurea grease use a #1 lithium base grease. Add a permanent zerk to the top port, remove the lower plug and add a couple "shots" then get the motor hot / run for at least 30 minutes. Then re-install the lower plug. Depending on the amount of run time - you probably only need to add grease every other year. If you run it a lot (like every day for 8 hours) then you'd need to add each 12 months.

Otherwise, do it every other year.

Otherwise, do it every other year.