- Joined

- Dec 25, 2011

- Messages

- 10,511

Yes, that's what he means. And explains something about your photographs that puzzled me until I got distracted by something else and forgot to ask about it.

Also, to combine replies to two posts into one, the chart that Pierre posted is the same as the 9" chart. And I just noticed something on the 9" chart when I blew it up that I hadn't noticed before. It actually says "Threading Chart for 9" and 10" with 5/8" diameter lead screw". So the 96T change gears went away with the appearance of the 3/4" dia. lead screws.

Pierre, could you send me direct the JPG of that chart? I'm not sure I can do anything useful with the .MHT. The one I have has suffered distortion from paper stretch in the original and multiple copying cycles.

Robert D.

Also, to combine replies to two posts into one, the chart that Pierre posted is the same as the 9" chart. And I just noticed something on the 9" chart when I blew it up that I hadn't noticed before. It actually says "Threading Chart for 9" and 10" with 5/8" diameter lead screw". So the 96T change gears went away with the appearance of the 3/4" dia. lead screws.

Pierre, could you send me direct the JPG of that chart? I'm not sure I can do anything useful with the .MHT. The one I have has suffered distortion from paper stretch in the original and multiple copying cycles.

Robert D.

The babbits were surprisingly good. I guess that was one of the few things the last owner did for maintenance .He was using it strictly as a wood lathe and the complete headstock area was packed with a nasty oil\sawdust mix.

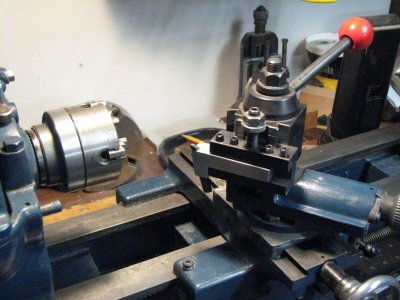

Here is a caption that went with the transmission picture .I can attest to the fact of picky engagement from neutral but it sounds like it might be worth it if you can go from forward to reverse during threading and not lose sync. I am not sure if that is exactly what they are saying but I will try it first chance.

Leadscrew reversing gearbox comparison: instead of face dogs on the outside of the ZAMAK bevel gears (as on later machines and shown in the gearbox at the top of the picture and the gear in the right of the foreground), this early lathe had a "half-the-circumference" dog cast onto the inside of the bevel gears - with a matching dog on the slider - so giving (because of its single location in/out setting) a "dog-clutch" that could be used to exactly pick up the thread-engagement point when screwcutting. The disadvantage would have been a reluctance to engage quickly - and hence the change to a multi-dog arrangement that was much faster to operate.

Wayne F