Hi all

I decided to cnc my warco wm14 mill and went from no cnc knowledge to having a pretty good understanding, all from this forum and your cnc builds!

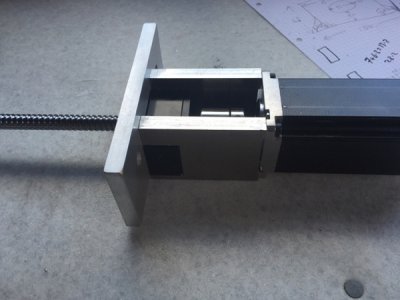

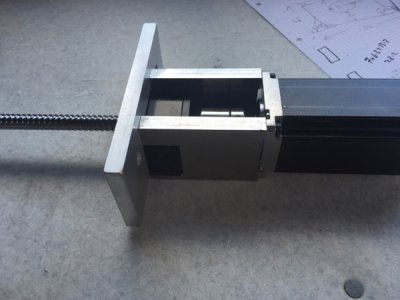

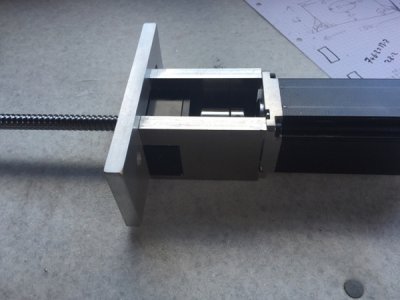

This is still in progress and I'm just waiting for arrival of a 12 mm ball screw for the x axis

Warco wm14

Stepper motor kit from longs motors

Dual boot old Mac with Windows xp - no parallel port so I needed to buy a uc100

Recycled an old speaker panel for electronics, just using an mdf box until I buy a computer enclosure.

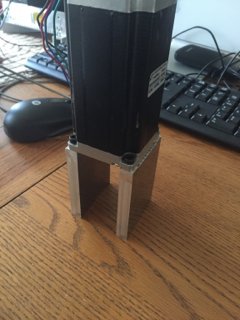

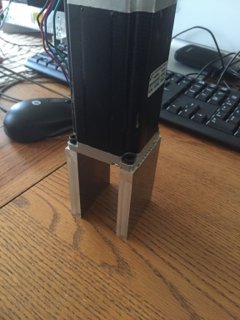

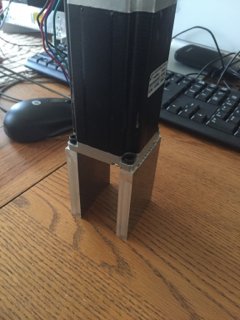

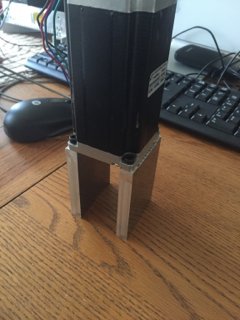

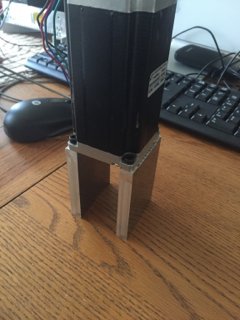

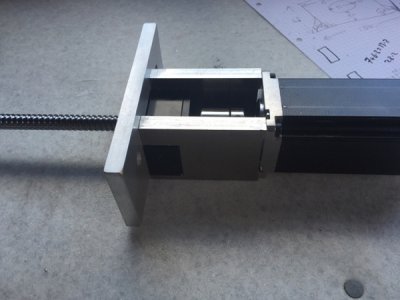

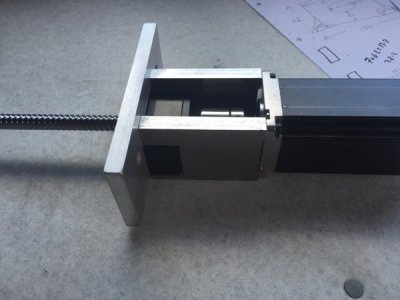

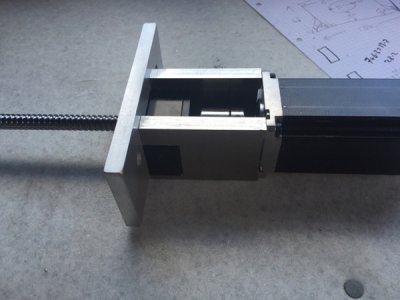

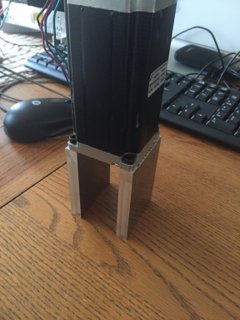

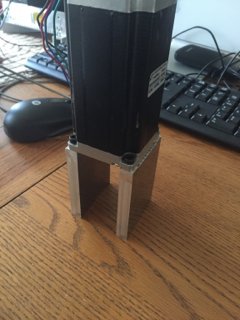

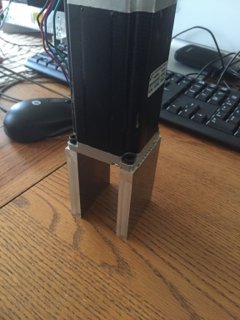

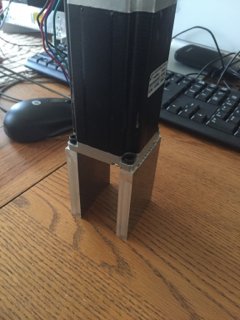

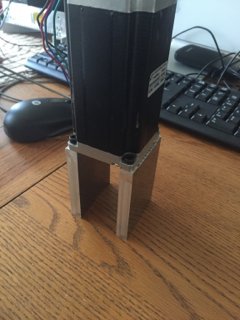

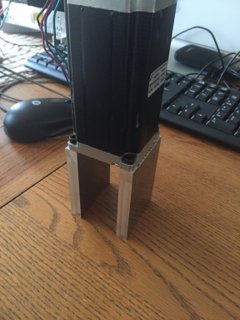

Started milling the mounts and I know this will need to be modified before I'm done!

X axis mount

Sent from my iPhone using Tapatalk

I decided to cnc my warco wm14 mill and went from no cnc knowledge to having a pretty good understanding, all from this forum and your cnc builds!

This is still in progress and I'm just waiting for arrival of a 12 mm ball screw for the x axis

Warco wm14

Stepper motor kit from longs motors

Dual boot old Mac with Windows xp - no parallel port so I needed to buy a uc100

Recycled an old speaker panel for electronics, just using an mdf box until I buy a computer enclosure.

Started milling the mounts and I know this will need to be modified before I'm done!

X axis mount

Sent from my iPhone using Tapatalk