- Joined

- Jul 20, 2012

- Messages

- 1,242

I am going to start this thread for posting any modifications for the Wabeco 6000 or any other Wabeco lathe. Anyone else please post up!

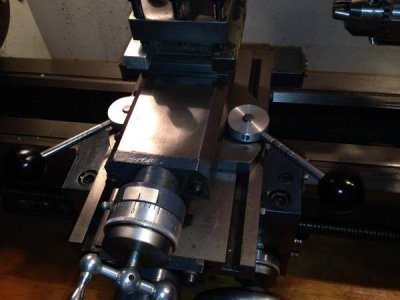

First one, simple tailstock lock

I know some newer models have a cam lock lever for this but this is an easy way to get simple locking without a wrench.

I noticed it took less than a quarter turn with a wrench to lock the tail stock down so I made a "Nut" with some stock aluminum (10X1.5 thread.) Put it on instead of the standard nut. Turn until it locks and mark for a handle to drill and tap to fit right where it will lock with a pull to the left and unlock when back to the right. It works great, easy to lock and unlock with no wrench.

The handle is made from a 6 inch stainless steel bolt 5/16 18 thread. I cut one end off and threaded it to fit on a ball same thread. You can see the witness marks from the chuck while threading, stainless is hard and I could't keep it from spinning.

First one, simple tailstock lock

I know some newer models have a cam lock lever for this but this is an easy way to get simple locking without a wrench.

I noticed it took less than a quarter turn with a wrench to lock the tail stock down so I made a "Nut" with some stock aluminum (10X1.5 thread.) Put it on instead of the standard nut. Turn until it locks and mark for a handle to drill and tap to fit right where it will lock with a pull to the left and unlock when back to the right. It works great, easy to lock and unlock with no wrench.

The handle is made from a 6 inch stainless steel bolt 5/16 18 thread. I cut one end off and threaded it to fit on a ball same thread. You can see the witness marks from the chuck while threading, stainless is hard and I could't keep it from spinning.