- Joined

- Feb 2, 2016

- Messages

- 55

HI all,

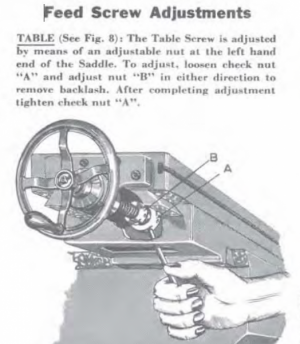

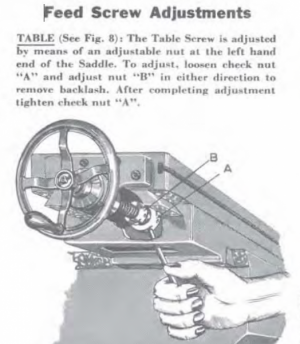

I have attempted to follow the instructions in the VN12 manual to adjust the table feed backlash. I have been unable to loosen the check nut "A" in the diagram below. Which way should I be attempting to turn it it to loosen it? Should I be pushing or pulling from the perspective of the diagram below. I assumed I was to push to have the nut move away from nut "B", but I have had no success (bending the 1/4" bars that I have been using). I also tried the other direction without any luck either.

Any help would be much appreciated.

Thanks,

Greg

I have attempted to follow the instructions in the VN12 manual to adjust the table feed backlash. I have been unable to loosen the check nut "A" in the diagram below. Which way should I be attempting to turn it it to loosen it? Should I be pushing or pulling from the perspective of the diagram below. I assumed I was to push to have the nut move away from nut "B", but I have had no success (bending the 1/4" bars that I have been using). I also tried the other direction without any luck either.

Any help would be much appreciated.

Thanks,

Greg