- Joined

- Oct 7, 2020

- Messages

- 94

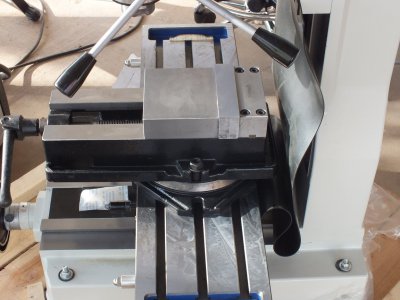

How big is too big? How much of the vise can reasonably hang over the front edge of the mill bed? A 6" vise is so heavy, my intuition tells me that the weight of the overhang would twist the milling bed over time-- but I'm a complete novice, so I don't trust my intuition at all.

I purchased a used 6" Kurt vise, but I'm afraid to put it on-- the mill bed is 7" deep, whilst the vise is 17" deep! I've got a 4" vise, and it looks more appropriately sized (it's only 9" deep), but it's also pretty limiting-- I've done very little with my mill so far, but I've already run into multiple situations where I'd really, really like those extra 2".

Any advise would be appreciated.

I purchased a used 6" Kurt vise, but I'm afraid to put it on-- the mill bed is 7" deep, whilst the vise is 17" deep! I've got a 4" vise, and it looks more appropriately sized (it's only 9" deep), but it's also pretty limiting-- I've done very little with my mill so far, but I've already run into multiple situations where I'd really, really like those extra 2".

Any advise would be appreciated.