-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vibration in Craftsman/Atlas 101 12x24 lathe

- Thread starter JPMacG

- Start date

- Joined

- Feb 7, 2011

- Messages

- 5,039

Don't try to use a puller on it it will break. loosen every thing on that shaft and tap it through the pulley. That is how I get mine off. I am all for a 3 phase motor and a vfd, but I would not get rid of any of the drive train. If your pulley is warped Clausing sales a updated one for about $92.00 shipped.

Last edited by a moderator:

- Joined

- Dec 25, 2011

- Messages

- 10,515

JPMacG,

The reasons for not getting rid of all (or any) of the stepped pulleys if you change the motor to one of the several kinds of variable speed ones are threefold. One is that the useful delta-RPM range of the variable speed motor is probably going to be less than the range of the 8-step pulley system. Two is that most variable speed motors have a torque capability proportional to the RPM and the low end torque may be inadequate (and if you go to a much higher HP motor to offset this you may cause other problems). The third is that the cooling fan normally runs at motor RPM and the motor will probably overheat at low RPM.

Going to a 4-step motor pulley would probably be a workable solution but the step farthest from the motor is a long way from the bearing and you might bend the motor shaft. Plus if you eliminate the countershaft, you'll have to not only find a motor pulley with the right ratio between steps but will also have to invent an easy to use belt tensioning mechanism. Because if it isn't easy to use, the human tendency will be to run the motor too slow rather than fight with a hard to use belt tensioner in order to change pulley steps.

Robert D.

The reasons for not getting rid of all (or any) of the stepped pulleys if you change the motor to one of the several kinds of variable speed ones are threefold. One is that the useful delta-RPM range of the variable speed motor is probably going to be less than the range of the 8-step pulley system. Two is that most variable speed motors have a torque capability proportional to the RPM and the low end torque may be inadequate (and if you go to a much higher HP motor to offset this you may cause other problems). The third is that the cooling fan normally runs at motor RPM and the motor will probably overheat at low RPM.

Going to a 4-step motor pulley would probably be a workable solution but the step farthest from the motor is a long way from the bearing and you might bend the motor shaft. Plus if you eliminate the countershaft, you'll have to not only find a motor pulley with the right ratio between steps but will also have to invent an easy to use belt tensioning mechanism. Because if it isn't easy to use, the human tendency will be to run the motor too slow rather than fight with a hard to use belt tensioner in order to change pulley steps.

Robert D.

- Joined

- Mar 22, 2014

- Messages

- 848

Thank you everyone! As usual, the information that I receive on this forum has been amazing. I won't have time to work on the lathe for the next several days, so I will just think it over. Right now I am thinking I will check the shaft runout and pulley fit and rework or replace one or both as necessary.

Yes, I would very much like to see a photo. Thanks! Are you sliding the motor in order to stay with the 2-step motor pulley that came with the lathe?

I tried to remove the large 2-step pulley last night. I would need a puller to get it off. It is definitely not a sloppy fit.

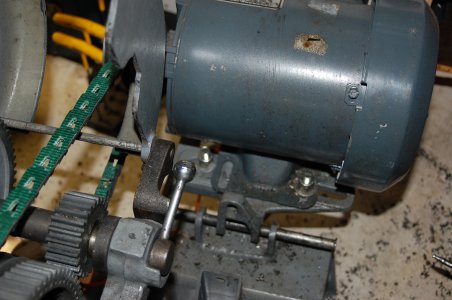

Sorry for the slow response... Busy around here lately... As you can see in the pics, the motor base is the original one from the countershaft assembly. The VFD is housed in a box along with a cooling fan and 12 volt power supply. I need to trim the cutout a little better and add a piece of Plexiglas over it. There are a few tweaks I need to make but its worked well so far.

Last edited: