-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

vfd use

- Thread starter JT.

- Start date

- Joined

- May 1, 2011

- Messages

- 484

You can set the VFD to control a range of speed (actually frequency). Mine on the lathe is set to to vary between 30 and 60 Hertz. If you need more then you can change the belts and/or use the backgear.

Your question is not very clear, but in general you cannot use the lathe's (or mill's) existing controls since they will disconnect the motor from the VFD power source-and that is a huge no-no. You can possibly rewire the existing controls to operate the VFD.

Clear as mud?

Your question is not very clear, but in general you cannot use the lathe's (or mill's) existing controls since they will disconnect the motor from the VFD power source-and that is a huge no-no. You can possibly rewire the existing controls to operate the VFD.

Clear as mud?

- Joined

- Nov 16, 2012

- Messages

- 5,596

I do something similar to KennyD but I still tend to use most of the gears on the machine just as I normally would. This is purely a matter of preference (neither is right or wrong). The advantage is that you tweak the speed up/down just a tiny bit (or as much as you want) to get the perfect speed and make best use of the motor's torque. Let's say you have a gear that's set for 840 RPM but your piece would really like to be cut at 800 RPM... -No problem, just tweak the VFD down a tiny bit.

It's OK to power-off the supply to the VFD but, it's not OK to put a switch in between the VFD and the motor. What many people do (including myself) is, connect the motor's power supply input lines to the input of the VFD then, put the VFD output to the motor input terminals. This way, your normal on/off switch still works as does any other electronics that might be present in the equipment. This is a safe/easy approach. Complications arise when the equipment normally had 2-speed motors and you need the schematic to see how to best deal with the wiring.

Ray

EDIT: It's generally not a good idea to run a motor at speeds less than 75% of it's nominal rating since older motors may rely on fan cooling and the fan won't spin fast enough to keep it cool. Unless the motor states otherwise, it's not advisable to exceed 60Hz. These are ballpark guidelines (45 to 60 Hz) and you need to check the specs on your motor to be certain.

It's OK to power-off the supply to the VFD but, it's not OK to put a switch in between the VFD and the motor. What many people do (including myself) is, connect the motor's power supply input lines to the input of the VFD then, put the VFD output to the motor input terminals. This way, your normal on/off switch still works as does any other electronics that might be present in the equipment. This is a safe/easy approach. Complications arise when the equipment normally had 2-speed motors and you need the schematic to see how to best deal with the wiring.

Ray

EDIT: It's generally not a good idea to run a motor at speeds less than 75% of it's nominal rating since older motors may rely on fan cooling and the fan won't spin fast enough to keep it cool. Unless the motor states otherwise, it's not advisable to exceed 60Hz. These are ballpark guidelines (45 to 60 Hz) and you need to check the specs on your motor to be certain.

- Joined

- Jun 22, 2012

- Messages

- 1,552

You can set the VFD to control a range of speed (actually frequency). Mine on the lathe is set to to vary between 30 and 60 Hertz. If you need more then you can change the belts and/or use the backgear.

Your question is not very clear, but in general you cannot use the lathe's (or mill's) existing controls since they will disconnect the motor from the VFD power source-and that is a huge no-no. You can possibly rewire the existing controls to operate the VFD.

Clear as mud?

Wow, I'm glad I saw this. I am getting ready to purchase a vfd for my heavy ten restoration and I wanted to use the original switch, so if I am understanding this right the original cuttler-hammer switch cannot be used with a vfd as it will disconnect power fed from the vfd and that's not good. Now I am unsure what I will do. Also if I am understanding this right, the only way to turn the lathe on and off is with the vfd? I kinda like the idea of being able to reach up and hit the kill switch for safety's sake. And then there's your last statement, "you can possibly rewire the controlls to operate the vfd" Now I'm intrigued, can the original switch be used to operate the vfd? That would be great if it could.

- Joined

- May 1, 2011

- Messages

- 484

Wow, I'm glad I saw this. I am getting ready to purchase a vfd for my heavy ten restoration and I wanted to use the original switch, so if I am understanding this right the original cuttler-hammer switch cannot be used with a vfd as it will disconnect power fed from the vfd and that's not good. Now I am unsure what I will do. Also if I am understanding this right, the only way to turn the lathe on and off is with the vfd? I kinda like the idea of being able to reach up and hit the kill switch for safety's sake. And then there's your last statement, "you can possibly rewire the controlls to operate the vfd" Now I'm intrigued, can the original switch be used to operate the vfd? That would be great if it could.

Greg, there are many threads on this. You simply rewire your machine's switch for low-voltage control so it will operate the VFD's F-N-R functions, and you can add a pot (potentiometer) to control speed as well.

Here is a thread to read: http://www.hobby-machinist.com/showthread.php/8009-A-VFD-write-up-for-a-Webb-Mill?p=66247#post66247 as an example even though he used a external switch.

Another one: http://www.hobby-machinist.com/showthread.php/7757-Wire-a-drum-switch-to-a-Teco-FM50

Anyway, I suggest you start your own thread and provide details and pictures of your motor and switch when your ready. We can also suggest the proper VFD with that info.

- Joined

- Jun 22, 2012

- Messages

- 1,552

Greg, there are many threads on this. You simply rewire your machine's switch for low-voltage control so it will operate the VFD's F-N-R functions, and you can add a pot (potentiometer) to control speed as well.

Here is a thread to read: http://www.hobby-machinist.com/showthread.php/8009-A-VFD-write-up-for-a-Webb-Mill?p=66247#post66247 as an example even though he used a external switch.

Another one: http://www.hobby-machinist.com/showthread.php/7757-Wire-a-drum-switch-to-a-Teco-FM50

Anyway, I suggest you start your own thread and provide details and pictures of your motor and switch when your ready. We can also suggest the proper VFD with that info.

Very good, I was hoping that I could use the switch to controll the vfd. Thank you for the reply, I will post pics of the motor tag and the switch in a new thread. Thanks for the advice.

- Joined

- Jul 7, 2012

- Messages

- 144

after reading my post a bearly understand my self what i wrote :thinking:

so here i go again

on the old continent we got 220V mono for home use 3x220v (old configuration ) ore 3x380v+N (indistrial power )

i bought a lathe withe a 3x220 V motor with a transformator so it runs on the 380 V now

in my workshop where i want to install the lathe i only got 220V mono

i can install the 380 option but then i need to run a 380v line to my workshop ( instalation in electrical cabinet + 60 yrds to my shop with al the hardware and manhours i think 500-700 $)

so i was thinking on the VFD option so i can run it on the 220V mono (250 $) but way more controle on the lathe speed etc. )

only drawback is from what read here is that i can not use the original lever without rewiring it .

i understand i can rewire it so the originale lever can act like a the remote controle from the VFD

i probably lose the dual speed function from the lever but F/O/R will do also

how do i do that ?

so here i go again

on the old continent we got 220V mono for home use 3x220v (old configuration ) ore 3x380v+N (indistrial power )

i bought a lathe withe a 3x220 V motor with a transformator so it runs on the 380 V now

in my workshop where i want to install the lathe i only got 220V mono

i can install the 380 option but then i need to run a 380v line to my workshop ( instalation in electrical cabinet + 60 yrds to my shop with al the hardware and manhours i think 500-700 $)

so i was thinking on the VFD option so i can run it on the 220V mono (250 $) but way more controle on the lathe speed etc. )

only drawback is from what read here is that i can not use the original lever without rewiring it .

i understand i can rewire it so the originale lever can act like a the remote controle from the VFD

i probably lose the dual speed function from the lever but F/O/R will do also

how do i do that ?

- Joined

- May 1, 2011

- Messages

- 484

OK JT now we are making progress!

Your 220v "Mono" is what we call single or 1 phase power, and your 3x220 is what we call 3-phase.

Yes, you will wire the motor directly to the VFD, and then you will have to identify what contacts in you switch are open/close in the different positions with a ohm-meter or simple continuity tester. You will loose the dual speed function, but thats OK.

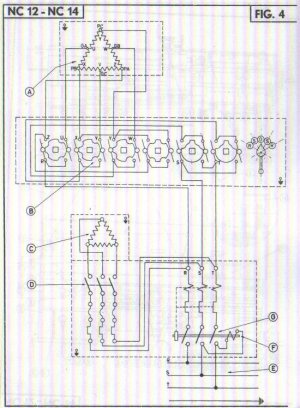

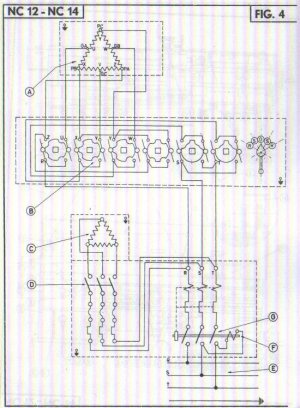

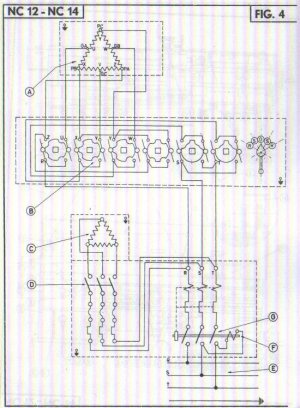

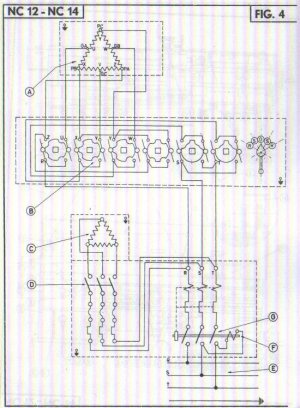

Does your machine have two motors? A and C in the diagram? Can you provide a key/description for the other letters please?

Your 220v "Mono" is what we call single or 1 phase power, and your 3x220 is what we call 3-phase.

Yes, you will wire the motor directly to the VFD, and then you will have to identify what contacts in you switch are open/close in the different positions with a ohm-meter or simple continuity tester. You will loose the dual speed function, but thats OK.

Does your machine have two motors? A and C in the diagram? Can you provide a key/description for the other letters please?

- Joined

- Jul 7, 2012

- Messages

- 144

OK JT now we are making progress!

Your 220v "Mono" is what we call single or 1 phase power, and your 3x220 is what we call 3-phase.

Yes, you will wire the motor directly to the VFD, and then you will have to identify what contacts in you switch are open/close in the different positions with a ohm-meter or simple continuity tester. You will loose the dual speed function, but thats OK.

Does your machine have two motors? A and C in the diagram? Can you provide a key/description for the other letters please?

nope only one .

A main motor

B switch /phase inverter

C cooling pumpmotor

D cooling pump switch

E power supply

F minima of tension

G main switch

- Joined

- Jul 7, 2012

- Messages

- 144

so i need a VFD 2.2KW some one got an idea if the VFD on flebay is any good ?http://www.ebay.co.uk/itm/UPDATED-N...ial_Automation_Control_ET&hash=item43acaa0403

ore is thise a better one

http://www.ebay.co.uk/itm/3-HP-DIGI...ial_Automation_Control_ET&hash=item589a2d67d7

ore is thise a better one

http://www.ebay.co.uk/itm/3-HP-DIGI...ial_Automation_Control_ET&hash=item589a2d67d7