- Joined

- Oct 31, 2015

- Messages

- 469

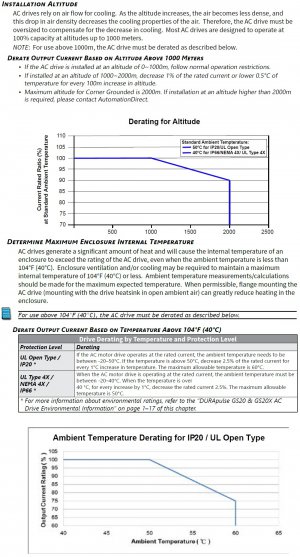

When researching specifications for VFDs, I keep seeing it called out that the unit is to be installed at or below 1,000 m (3,280 ft) above sea level. I struggle to see how that is pertinent to an electronic device, but I'm definitely no expert. Since my shop elevation is about 4,000 ft (1,219 m), I would be out of spec.

My instinct is to ignore this requirement, but I figured I'd ask the brain trust. Is this really important? If so, why?

My instinct is to ignore this requirement, but I figured I'd ask the brain trust. Is this really important? If so, why?