- Joined

- Dec 18, 2019

- Messages

- 6,447

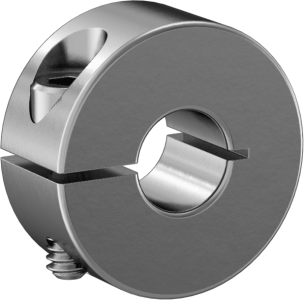

You have a mill and a lathe. You could make that piece then. Technically, you could drill that hole in your lathe with a four jaw chuck (after filing a flat for the drill to start). It might be easier on a mill though. People have made a lot of sophisticated stuff with hand tools. To make that slit by hand I would use a fine toothed saw. It wouldn't be difficult, especially if the piece was brass. But since you have a mill now, I'd just use a slitting saw.

Under the Projects Forum, there is a Member's Project subforum. I think that is the logical place. It is your project, is it not? But you could just start a thread in Metrology. Or start a thread in the Member's Project area. Either way.

This is a cool project. Definitely would be good for all your earlier posts on this project to be swept up and put in a common place. Might want to contact a Moderator to see if they can help with that.

Under the Projects Forum, there is a Member's Project subforum. I think that is the logical place. It is your project, is it not? But you could just start a thread in Metrology. Or start a thread in the Member's Project area. Either way.

This is a cool project. Definitely would be good for all your earlier posts on this project to be swept up and put in a common place. Might want to contact a Moderator to see if they can help with that.