- Joined

- Feb 1, 2015

- Messages

- 9,937

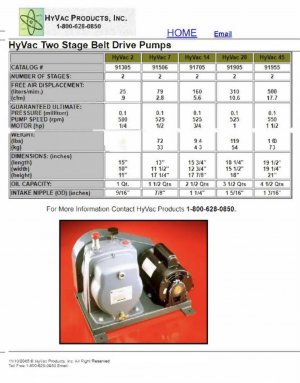

The company that I worked for 35 years ago made epoxy composites. The epoxy was mixed in a vacuum chamber to prevent air inclusions. I did some experiments with evacuating the chamber with the epoxy components and. as you say, when the vacuum dropped down to below 20 microns, the Jeffamine hardener would froth. The amount of frothing could be controlled with the amount of vacuum pulled but it wouldn't subside over time. My conclusion was that ir wasn't a case of moisture ir included air but rather the Jeffamine itself was boiling or decomposing. This was in contradiction to the published vapor pressure specs.If the epoxy isn't thinned, probably OK. However, one thing I learned when trying to de-air epoxy with a vacuum pump is that it can froth over in a heartbeat if the pressure gets too low. I'm not sure what caused it -- dissolved water (or air??), some organic component with a a relatively high vapor pressure/whatever -- but it definitely caused problems for me in that regard. It was bad enough that I worried about the stuff getting into the vacuum pump (it didn't).

We used Varian rotary vane pumps capable of pulling better than a 10 micron vacuum. To measure vacuum, we used thermocouple gauges that were calibrated with a Mc Leod gauge to meet ISO9000 requirements.. The chambers we used were made from 1/2" aluminum plate with a 1" thick Plexiglas door and were about 24" cubes.