- Joined

- Dec 25, 2012

- Messages

- 184

Hi Jeff, Yes I have a QCTP and also a four way. The lathe is a Clarke CL300M otherwise known as a Siege c2. 300mm between centres 180mm over bed. zero - 3000rpm with uprated motor.

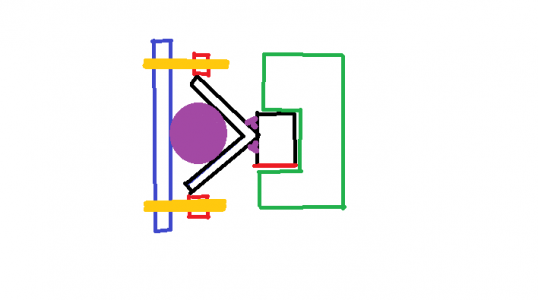

180mm is just over 7" ( for the non metric folks). Have a friend with a welder? Whatever your maximum width bar you can fit in your tool holder, use that for mounting. Use a piece of angle iron 1-1/2" on each leg and have nuts welded on each end. Use a strap to tighten the part in the V. If the part is shorter than the depth of the V, place a small piece of flat bar under the strap to hold it in place.

Jeff