- Joined

- Aug 29, 2016

- Messages

- 838

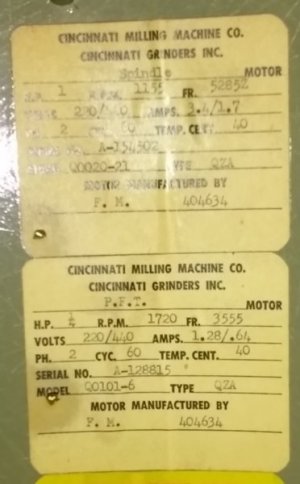

So I got the new mill home and was cleaning it up some. I found the serial number. And the production date of 1960. And 220V as expected. and Ph = 2. Two. Definitely a 2. So I look at the spindle motor. 220V 2P. We ran this at the sellers place off of a static converter, and it came with a 3 hp RPC.

I'm about to start tracing wires. I know that in 1890 Ph=2 means I screwed today. But two phase was dead LONG before this machine was built. I'm doing the research, but hopefully someone has a clue what this is about. Did Cincinnati really build 2 ph machines in 1960?

I'm about to start tracing wires. I know that in 1890 Ph=2 means I screwed today. But two phase was dead LONG before this machine was built. I'm doing the research, but hopefully someone has a clue what this is about. Did Cincinnati really build 2 ph machines in 1960?