-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turning your Logan into a Horizontal boring machine....

- Thread starter Richard White (richardsrelics)

- Start date

- Joined

- Dec 3, 2015

- Messages

- 243

Good Lord willing and me being able I expect another 30 years out of this machine. Plans are when I retire to use that time to make parts for others in our club of Antique Outboard enthusiast. I have contemplated pillow block bearings as they have the ones that can be so called self-centering... But that would entail a whole new part, if I go that far to make a new part I will use sealed bearings.

- Joined

- Apr 30, 2015

- Messages

- 11,255

- Joined

- Mar 3, 2017

- Messages

- 743

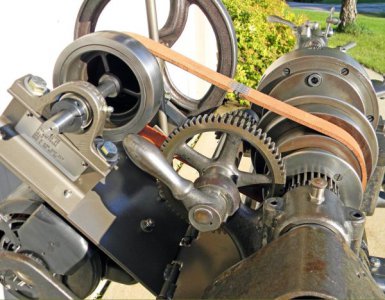

Put the shaft thru the fork, and attach one shaft end at your... you will find 2 photos that show no bushings but plenty of room for some. It has a keyway, but in that keyway was an oil wick. Well as you can see from this photo that got neglected early on..

View attachment 231341

If I go the sealed bearings, I am probably going to need it line bored...

tailstock; then you can use a steady rest to hold the shaft

near the OTHER end of the fork and dial it in. The yoke

will slide on the aligned shaft.

Then a lathe is lined up for boring it for a bushing. (tool

held in the spindle, work advanced by hand, or try attaching

somehow to the compound).

If your transverse oil holes can be

opened up afterward, the performance of oiled steel-on-bronze might

be good enough for a few decades.

- Joined

- Oct 18, 2016

- Messages

- 2,872

Don't know what you decided to do here, but eBay has an early Model 200 countershaft support for sale with a starting bid of 30 bucks. You'd need bushings and their holders

(which are also on eBay) but it might be worth considering.

(which are also on eBay) but it might be worth considering.

Last edited: