- Joined

- May 2, 2014

- Messages

- 217

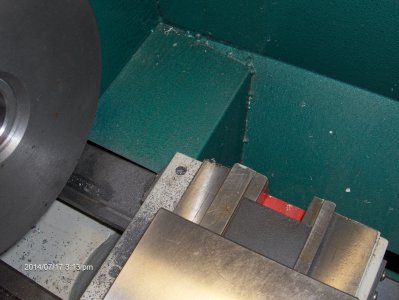

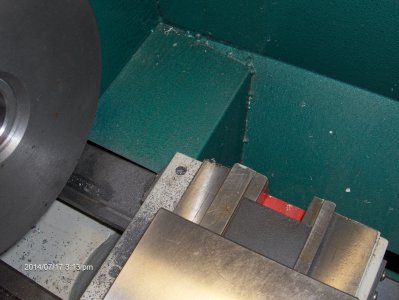

FRUSTRATION! I recently bought an ER40 flat back collet chuck and an unmachined backplate. I threaded the backplate on the spindle nose and was setting up to turn the OD and machine a registry diameter on the face.

I can't get close enough to the plate to machine it. The carriage hits the backsplash. If I remove the backsplash, I still can't get in close enough because the carriage will hit the headstock. I might be able to do it if I hang the tool out as far as I can and wind the compound rest all the way out, which leaves it unsupported.

I need a hockey stick tool!

I am going to buy a quick change tool post to replace the turret that came with the machine. It is too limited and shims have to be used to center the tools. That's another story.

OK, how have any of you machined a backplate on a Grizzly 0602?

I can't get close enough to the plate to machine it. The carriage hits the backsplash. If I remove the backsplash, I still can't get in close enough because the carriage will hit the headstock. I might be able to do it if I hang the tool out as far as I can and wind the compound rest all the way out, which leaves it unsupported.

I need a hockey stick tool!

I am going to buy a quick change tool post to replace the turret that came with the machine. It is too limited and shims have to be used to center the tools. That's another story.

OK, how have any of you machined a backplate on a Grizzly 0602?