-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trying To Decide On A Mill

- Thread starter Navy Chief

- Start date

- Joined

- Jan 10, 2014

- Messages

- 200

We are always willing to talk you into spending 200% of your budget, and then some....

Mostly because many of us got talked into it, and we are just paying it forward....

Uh huh...and you will thank us later

Uh huh...and you will thank us later

Fully agree... it looks like too much machine... until one gets busy and determines it is maybe not enough machine (no machine remains enough machine forever... LOL).

How are you doing Morgan...

I FINALLY have both my machines... the lathe should be running in a few days.

- Joined

- Jan 10, 2014

- Messages

- 200

I am well, thank you. Hope you are, too. I went through the which-mill-should-I-get a few weeks ago as well. The PM25 was on the top of my list, being a size that will fit in my space and just within my budget. Many of you (without realizing yall were doing it) talked me into blowing the budget and getting the 932...just like yall did when I wanted an 1127 lathe and ended up with the 1236!

I have not used the 932 yet, but I will say that it looks like a very sturdy machine and the cast iron base it comes with is very nice. It seems like a good size hobby machine and fits well in a small space (I have one car space in my garage as my shop area). It is the biggest machine that I have room for.

OP, I would suggest getting the largest, beefiest machines you can fit in your space and can reasonably almost afford. I went over my budget on both my machines (not by more than I could handle) and am glad I decided to. I have had to wait on a few other things like tooling, but it is nice knowing that my machines will handle anything that I will (probably) be throwing at them.

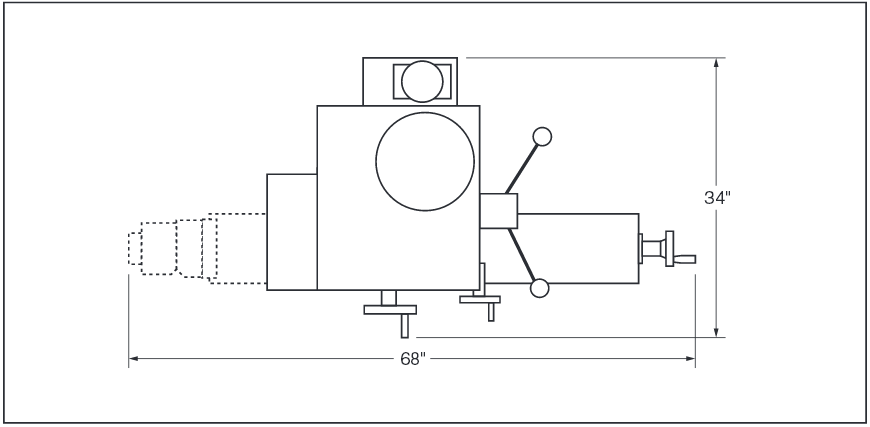

For floor space, I went by this diagram that I found online for this style mill:

Good luck with your decision, both of the machines you named are well liked by their owners, and Matt is great to do business with, so either way you should be good to go.

I will post up some pics of how I managed to fit everything into my small space once I have the mill up on the stand (waiting on the base to get welded and painted).

Keep us posted, and when you get it, post pics!

I have not used the 932 yet, but I will say that it looks like a very sturdy machine and the cast iron base it comes with is very nice. It seems like a good size hobby machine and fits well in a small space (I have one car space in my garage as my shop area). It is the biggest machine that I have room for.

OP, I would suggest getting the largest, beefiest machines you can fit in your space and can reasonably almost afford. I went over my budget on both my machines (not by more than I could handle) and am glad I decided to. I have had to wait on a few other things like tooling, but it is nice knowing that my machines will handle anything that I will (probably) be throwing at them.

For floor space, I went by this diagram that I found online for this style mill:

Good luck with your decision, both of the machines you named are well liked by their owners, and Matt is great to do business with, so either way you should be good to go.

I will post up some pics of how I managed to fit everything into my small space once I have the mill up on the stand (waiting on the base to get welded and painted).

Keep us posted, and when you get it, post pics!

- Joined

- Mar 10, 2015

- Messages

- 248

Chief,

I bought a used variable speed bridgeport (advertised as like new condition), it is currently completely disassembled, needs new bearings, motor, all the ways need to be scraped, it might end up being an expensive heavy floor drill press (I have kept it as a constant reminder to never buy any used heavy machinery on EBAY that I cannot go over with a fine toothed comb). I ended up buying a 1340gt and a 935 T-S (waiting to receiving them). I wish I had purchased them sooner, like years ago.

This is exactly what concerns me about buying used, the person selling the machine is getting rid of it for a reason. Sometime it is because they are done with it up upgrading, and sometimes it is because it is not worth the time, money, and effort to fix.

Unfortunately right now the budget is not going to allow for a PM935, the cost of the machine plus all of the tooling is prohibitive right now. Realistically I am going to end up with a PM25MV, or the Grizzly G0759 that I have been looking at for awhile (if they ever stock them again). The startup cost for these two machines is much more reasonable, and the work envelope on them will suit my needs for quite awhile (famous last words I am sure).

I really appreciate all of the comments and input from everybody, it has been great food for thought. Now back out to the garage to work on cleaning and re-arranging to make room to actually work out there...

- Joined

- Feb 12, 2014

- Messages

- 53

Hi Chief, Precision Matthews has good quality machinery in my opinion, I bought the PM836V because I got a really good deal and it is about 3/4 size to a full size mill. I also had somewhat of a space consideration and didn't want or need a full size mill. I am retired and spend my machine time building scale stationary steam engines and locomotives. So far I have not had an instance where I needed a bigger machine. The variable speed drive is well worth the money as I tire really fast changing belt positions. If you are a retired Navy guy, I'm sure you have the ability and skills to manufacture a quill feed for your choice of machines if it doesn't have that option. Mine works really well, gives me better control of feed rate and a better finish when boring cylinder bores. The accuracy of my machine is comparable to any that I have worked on in the last 35 years in the machine tool trade.I am in the planning stages of re-arranging my shop to make space for a mill and I need some help. I am trying to decide between the PM-25MV and the PM-932M-PDF. I am really leaning towards the larger machine so that in theory I will not outgrow it as soon, but I need to know how much floor space to plan for each of these machines so I can figure out what I can fit into the shop space I have. My planned usage right now is making telescope parts, motorcycle parts, model engines, and of course making tools, etc. Right now all I am working with is a 7x14 Grizzly lathe, and adding a mill to the shop would really open up the possibilities for projects.

I am also wondering if there is any advantage to having the 3 axis DRO on these types of machines, is the down feed on the column accurate enough and smooth enough to use it as a feed for working, or is it just rough setup with the quill being used for fine feeds?

Thanks for any information you can provide.

Best regards

Patrick

Army Veteran