- Joined

- Feb 2, 2020

- Messages

- 149

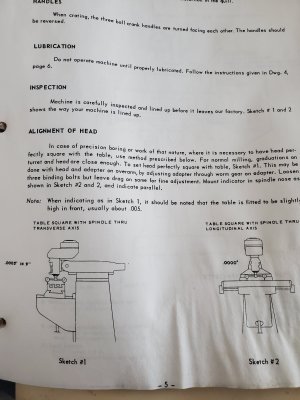

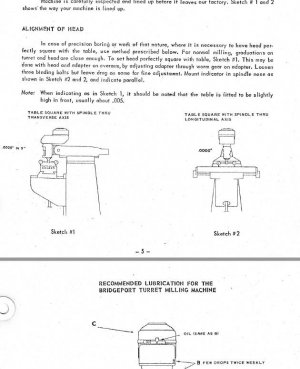

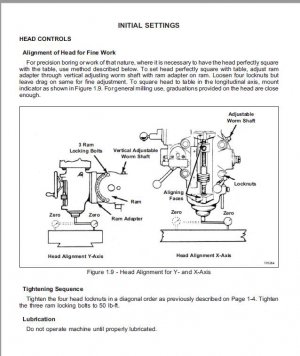

I noticed some small ridges in the x axis. I trammed my head just the other day. When I was milling some aluminum, I could see ridges but I couldn't feel them. On steel, it's much more noticeable. I glanced at my manual just a moment ago and it mentioned setting the front 0.005" higher than the back.

I'm assuming I need to raise the front up a little because of tool deflection. On aluminum, it's softer hence less deflection and less noticeable ridges. Am I correct in my thinking?

I'm assuming I need to raise the front up a little because of tool deflection. On aluminum, it's softer hence less deflection and less noticeable ridges. Am I correct in my thinking?