- Joined

- Apr 4, 2013

- Messages

- 655

Good day,

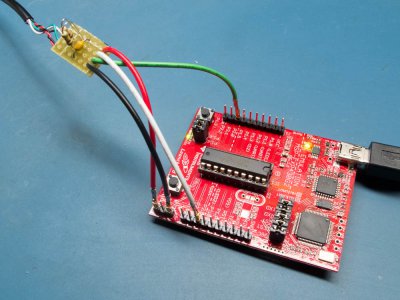

By popular demand, I finally added support for iGaging Absolute scales to the TouchDRO (using MSP430 "Universal" controller firmware).

The firmware is still in "BETA" version and can be downloaded from my blog's "Downloads" section (http://www.yuriystoys.com/p/downloads.html). In a few days I will post a detailed how-to guide, but here is the short version.

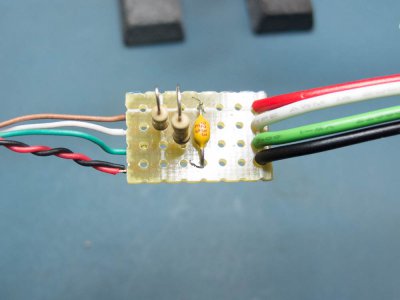

The USB cable that comes with the Absolute scales has 6 wires:

Brown - Vcc (+3V)

Red - Ground

White - Data

Green - Clock

Black - "Request"

For now you can cut into the cable (mine was not shielded, by the way) and connect Ground, Cock and Data to the corresponding MSP430 pins. (For details on the pinout, see this post: http://www.yuriystoys.com/2014/01/dro-interface-pin-functions-for-msp430.html)

The head needs to be connected for now (otherwise the reading head won't send the position). I will post a circuit that will bypass the reading head in a few days.

The position is read out in 0.01 mm (i.e. reading of 123 means 1.23mm), so the PPI in TouchDRO needs to be set to 2540.

I will keep posting the progress, but I hope this will be useful for some "brave souls".

Regards

Yuriy

By popular demand, I finally added support for iGaging Absolute scales to the TouchDRO (using MSP430 "Universal" controller firmware).

The firmware is still in "BETA" version and can be downloaded from my blog's "Downloads" section (http://www.yuriystoys.com/p/downloads.html). In a few days I will post a detailed how-to guide, but here is the short version.

The USB cable that comes with the Absolute scales has 6 wires:

Brown - Vcc (+3V)

Red - Ground

White - Data

Green - Clock

Black - "Request"

For now you can cut into the cable (mine was not shielded, by the way) and connect Ground, Cock and Data to the corresponding MSP430 pins. (For details on the pinout, see this post: http://www.yuriystoys.com/2014/01/dro-interface-pin-functions-for-msp430.html)

The head needs to be connected for now (otherwise the reading head won't send the position). I will post a circuit that will bypass the reading head in a few days.

The position is read out in 0.01 mm (i.e. reading of 123 means 1.23mm), so the PPI in TouchDRO needs to be set to 2540.

I will keep posting the progress, but I hope this will be useful for some "brave souls".

Regards

Yuriy