- Joined

- Aug 22, 2012

- Messages

- 4,121

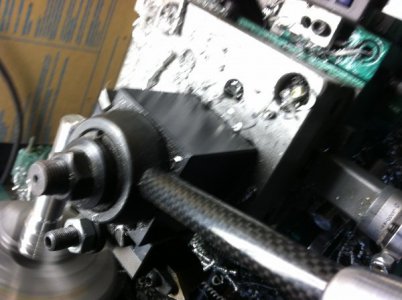

I have decided to make a plinth for the axa qctp on my 9x20 lathe.

I dont have a single chunk of steel I can make it from so it has to be in two parts.

The bottom part is 100 x 100 x 19 mm and the other part is 54mm dia 19mm thick.

The original bolt supplied with the qctp is 14mm dia but the hole in the qctp is 14.7mm.

Now the quandaries, I'm unsure which way to go now.

Should I turn a bolt to 14.65/68mm so its a good sliding fit in the tool post?

This seems the logical way to my inexperienced mind or keep it loose as it is at present.

Next do I weld the top 54mm dia puck to the base 100x100 square for extra rigidity.

Then bore them for a 14mm thread but bore half way through the top puck as an interferance fit for the final dia of the bolt so it screws down tightly into the base and puck.

I may be over thinking this but I'm attempting to remove as much possible areas of flex from the assembly.

I dont have a single chunk of steel I can make it from so it has to be in two parts.

The bottom part is 100 x 100 x 19 mm and the other part is 54mm dia 19mm thick.

The original bolt supplied with the qctp is 14mm dia but the hole in the qctp is 14.7mm.

Now the quandaries, I'm unsure which way to go now.

Should I turn a bolt to 14.65/68mm so its a good sliding fit in the tool post?

This seems the logical way to my inexperienced mind or keep it loose as it is at present.

Next do I weld the top 54mm dia puck to the base 100x100 square for extra rigidity.

Then bore them for a 14mm thread but bore half way through the top puck as an interferance fit for the final dia of the bolt so it screws down tightly into the base and puck.

I may be over thinking this but I'm attempting to remove as much possible areas of flex from the assembly.