- Joined

- May 7, 2023

- Messages

- 2,094

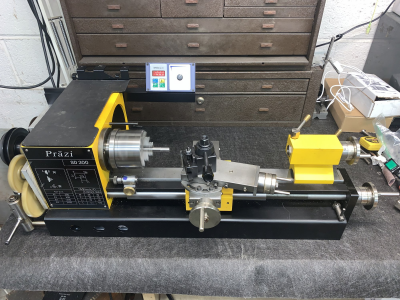

Our machines are some of the finest machines ever made in this size or class of machine.

In the past there were many competitors, but not all had the rigidity or power of the Prazi/H-Mat, so some specific tooling was created to help beginners deal with these other machines limitations. Im talking primarily the Sherline and Unimat machines, but there were others also.

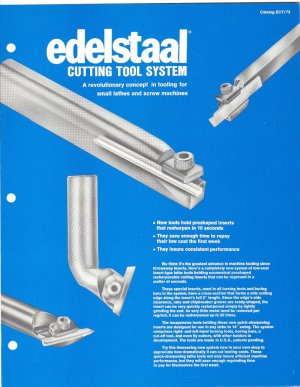

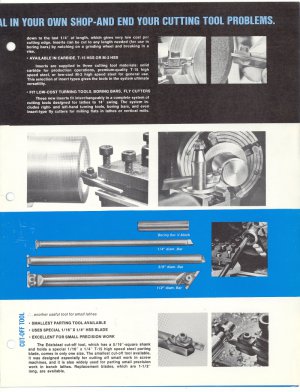

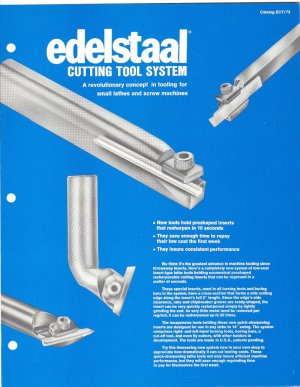

Edelstaal, the parent company of Unimat, marketed some rather unique tooling, or should I say a tooling system designed around the limited power and rigidity of the two rail bed and sewing machine motor of the Unimat.

This was an excellent system both in the way it helped new machinists deal with the learning curve of grinding a suitable cutting tool, but also in the way these tools help make good use of the limited power of these machines.

How does this help us? Well, with more rigidity and higher power of the PRAZI machines, this line of tooling really begins to shine.

I work as a Toolmaker and once I found these little tools and tool bits, I was hooked. They are pricy, don't get me wrong, but they are also so good I've been keeping them a secret for a while as I build up my supply.

The profile of the tool bits gives you 90% of what you need to make a good cutting tool bit with only the slightest touchup on a belt sander (My preference) or bench grinder.

The profile of the tool bits gives you 90% of what you need to make a good cutting tool bit with only the slightest touchup on a belt sander (My preference) or bench grinder.

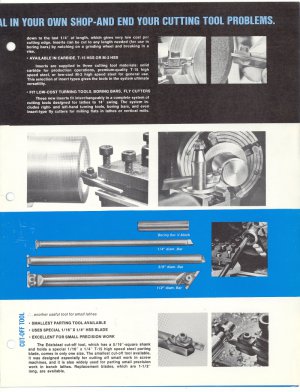

Literature from the 70s when these first became popular.

Now if the literature doesn't get your attention, how about a demonstration.

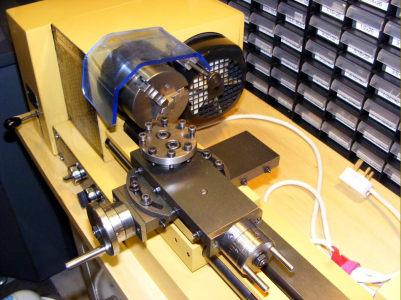

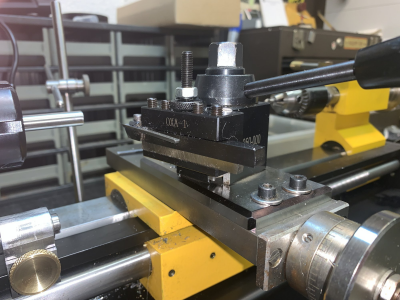

Heres my machine with the Custom Crafter drive system taking a .060 deep cut (.120 on diameter) with the T-15 (Red/cobalt) insert on 3/8" O-1 tool steel. RPMs vary from 36-800ish on this cut.

In the past there were many competitors, but not all had the rigidity or power of the Prazi/H-Mat, so some specific tooling was created to help beginners deal with these other machines limitations. Im talking primarily the Sherline and Unimat machines, but there were others also.

Edelstaal, the parent company of Unimat, marketed some rather unique tooling, or should I say a tooling system designed around the limited power and rigidity of the two rail bed and sewing machine motor of the Unimat.

This was an excellent system both in the way it helped new machinists deal with the learning curve of grinding a suitable cutting tool, but also in the way these tools help make good use of the limited power of these machines.

How does this help us? Well, with more rigidity and higher power of the PRAZI machines, this line of tooling really begins to shine.

I work as a Toolmaker and once I found these little tools and tool bits, I was hooked. They are pricy, don't get me wrong, but they are also so good I've been keeping them a secret for a while as I build up my supply.

Literature from the 70s when these first became popular.

Now if the literature doesn't get your attention, how about a demonstration.

Heres my machine with the Custom Crafter drive system taking a .060 deep cut (.120 on diameter) with the T-15 (Red/cobalt) insert on 3/8" O-1 tool steel. RPMs vary from 36-800ish on this cut.

Last edited: