- Joined

- Mar 21, 2013

- Messages

- 4,063

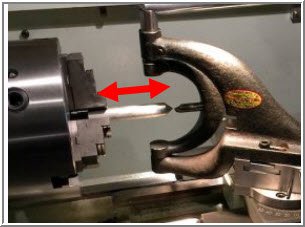

Well, I've have some time on my hands now, and saw a post about someone making knobs for their machines so I decided to break out the radius cutter and try using it to make a fwd/rev/stop knob for my lathe. I'd already made the feed and threading knobs a while back.

Setup was pretty easy. Even given it's heft.

I had the idea in my mind of a 1" diameter teardrop shaped knob like those I've seen on the SB. I decided halfway into making the major radius cut to do a small radius undercut below the dome. And then taper from there to the shaft. Should have stuck with the first (and much simpler) idea. I'm going to have to practice at this a bit before I feel even half way competent.

The setup was too flexy, allowing quite a bit of chatter. Had to go real slow and even then I had to take out a bunch of chatter marks. The undercut was especially bad, and by the time I got it smoothed out most of the radius was taken out. Oh well, it was a good learning experience. One I intend to do many times more.

Setup was pretty easy. Even given it's heft.

I had the idea in my mind of a 1" diameter teardrop shaped knob like those I've seen on the SB. I decided halfway into making the major radius cut to do a small radius undercut below the dome. And then taper from there to the shaft. Should have stuck with the first (and much simpler) idea. I'm going to have to practice at this a bit before I feel even half way competent.

The setup was too flexy, allowing quite a bit of chatter. Had to go real slow and even then I had to take out a bunch of chatter marks. The undercut was especially bad, and by the time I got it smoothed out most of the radius was taken out. Oh well, it was a good learning experience. One I intend to do many times more.