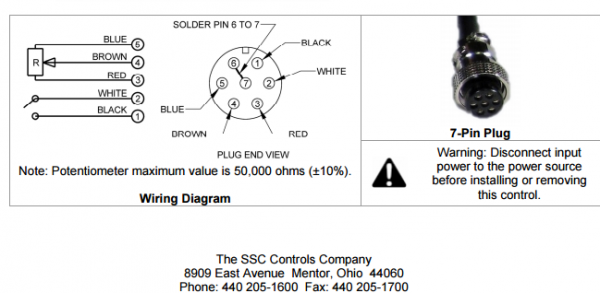

There can be some variations depending upon how your potentiometer is used. A potentiometer can be used as a simple variable resistor (rheostat) or as a voltage divider. If pin 4 is connected to either pin 3 or pin 6 or if either pin 3 or 6 is not connected to external circuitry, it is a rheostat. If pins 3,4, & 6 are connected to external circuitry, it could be used as a voltage divider but not necessarily.

A clue is the statement of 50 Kohm maximum. The implication is that there is an external resistance involved.

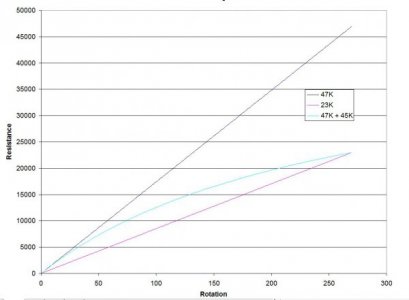

If used as a rheostat, the graph above would apply. You would still need to know whether to connect the 45K resistor from pin 4 to pin 3 or to pin 6 which would be determined by the rest of the circuitry. I can't see that you would do any harm by connecting it to the wrong pin; you just wouldn't get the response you are looking for.

If use as a voltage divider, an external resistor may be being used to limit the maximum (or minimum) voltage. For example if 10 volts were available to the current control circuit but 5 volts would provide maximum current, an external resistance of 50K would limit the maximum voltage from the divider to 50K/(50K + 50K) x 10 volts or 5 volts. Changing the potentiometer to 75K would give a maximum voltage from the potentiometer to 75K/(50K + 75K) x 10 volts or 6 volts. This would mean that you would reach full current at 5/6ths of the pot travel. Other values can make the changes more dramatic. In this case, I would probably place the 45K resistor across pins 3 & 6.

To really know what is going on, you would need to provide a more complete schematic. Otherwise it is a bunch of guesswork.