I'm wondering if the black oxide is the problem even with clean threads. Normally Crazy glue or red loctite should do the job. The black oxide might be acting as a release agent. When you separated the glued parts did the threads come out clean?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

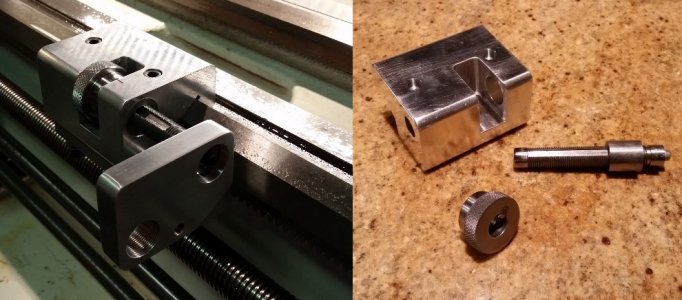

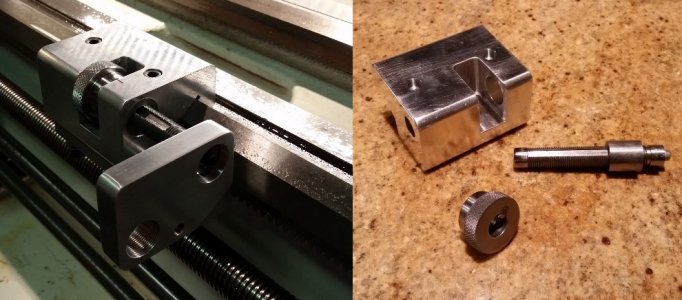

Thumb Screws From A Combination Of Materials

- Thread starter Ripthorn

- Start date

T

TOOLMASTER

Forum Guest

Register Today

LOCTITE TAKES A FEW DAYS TO TOTALLY WORK

- Joined

- Jun 12, 2014

- Messages

- 4,818

I also use the red Loctite, and agree it can take 2-3 days to set. I sometimes accelerate it by putting it in a warm oven (~200F). Parts need to be clean and free of contamination, there are certain types that fill voids better. Never had it fail, recently made an aluminum micrometer lathe stop with a steel thread bushing, which I secured in place with the red Loctite. They do have some high temperature variants, but I have used heat in the past to separate parts secured with standard red Loctite.