- Joined

- Jul 18, 2011

- Messages

- 224

A good buddy of mine was checking out my HQ recently and expressed interest in some of the custom bits I'd made for it. He's a got a really nice HQ Monaro (2 door coupe version of my car) with a 6.0L LS motor out of a VE Commodore (Pontiac G8) so I started last weekend by making him a nice cover for his wiper motor.

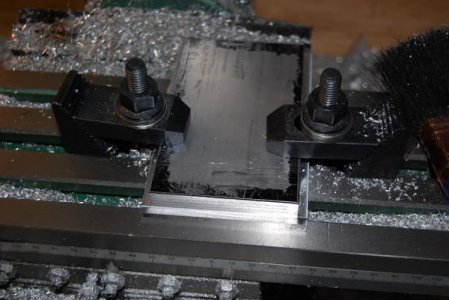

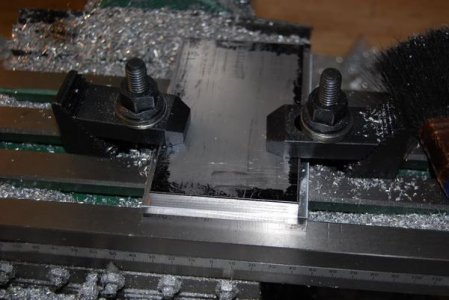

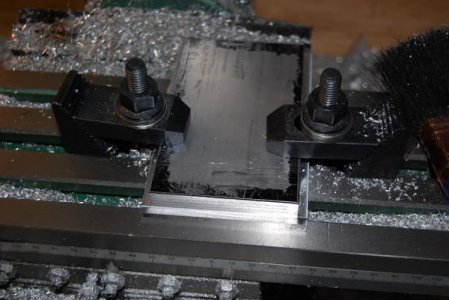

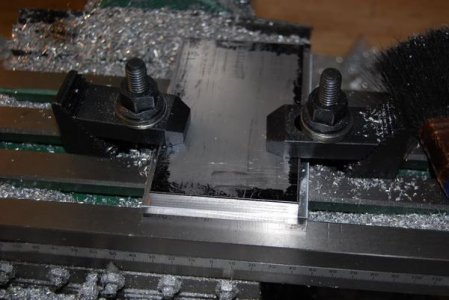

So this weekend I decided to make him a billet cover for his master cylinder. I started off by cutting off a piece of 80mm x 16mm aluminium on my bandsaw.

I faced off the ends

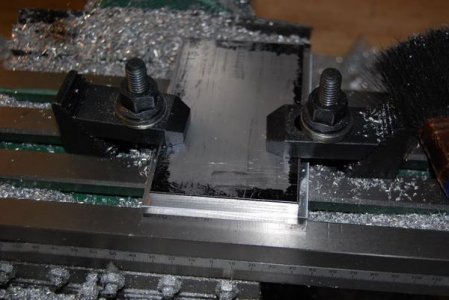

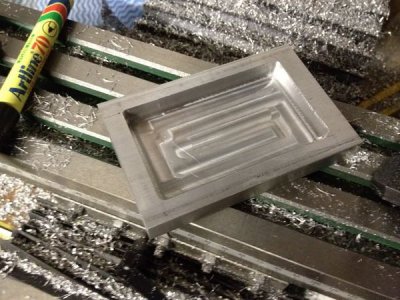

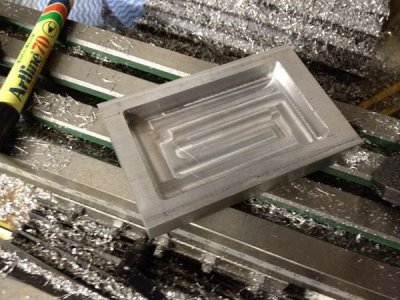

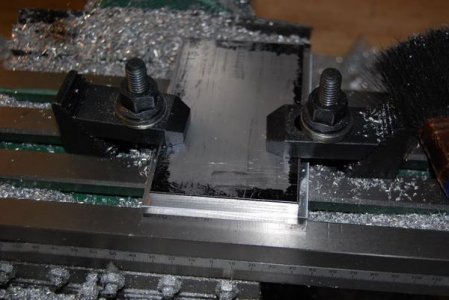

I started off by milling out the hollow section underneath, I used a ball mill to in the corners to round it off.

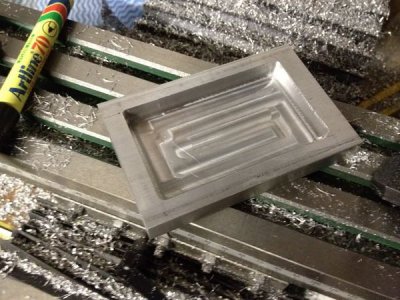

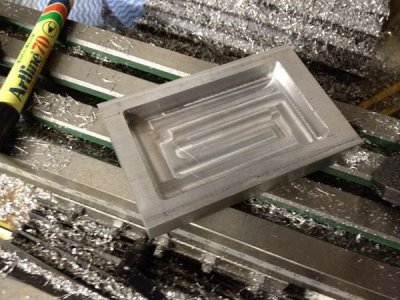

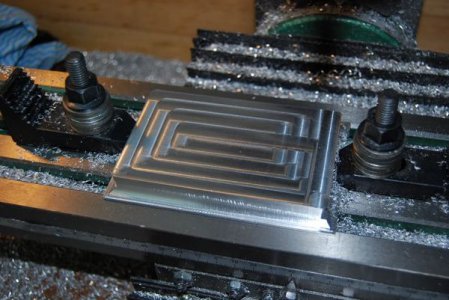

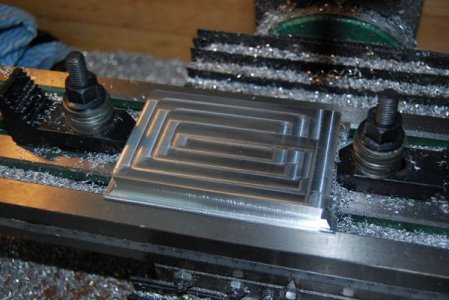

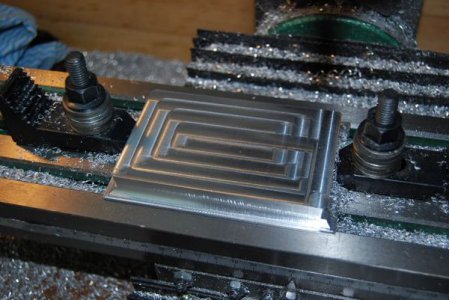

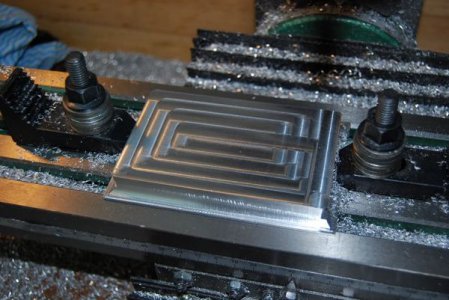

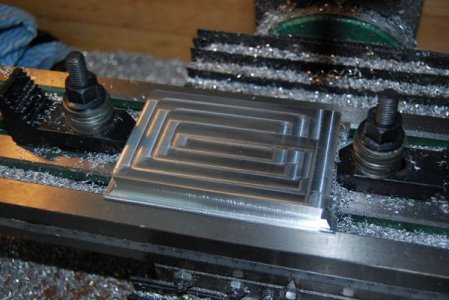

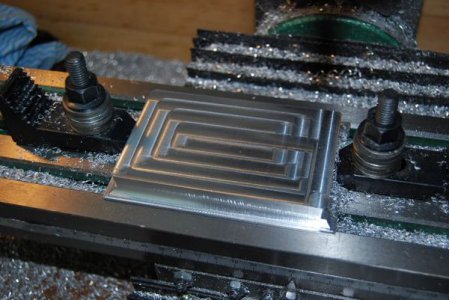

Then to the top, I rough milled the edges before ball milling them to get a nice rounded edge.

I used my rotary table to round of the corners, (forgot to get a pic) and then faced of the top with an end mill.

I finished it off with some ball milling on the top and a quick polish.

The finished product next to the original pressed tin one.

My buddy lives about 40 minutes away so I haven't had a chance to fit it yet

So this weekend I decided to make him a billet cover for his master cylinder. I started off by cutting off a piece of 80mm x 16mm aluminium on my bandsaw.

I faced off the ends

I started off by milling out the hollow section underneath, I used a ball mill to in the corners to round it off.

Then to the top, I rough milled the edges before ball milling them to get a nice rounded edge.

I used my rotary table to round of the corners, (forgot to get a pic) and then faced of the top with an end mill.

I finished it off with some ball milling on the top and a quick polish.

The finished product next to the original pressed tin one.

My buddy lives about 40 minutes away so I haven't had a chance to fit it yet