-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

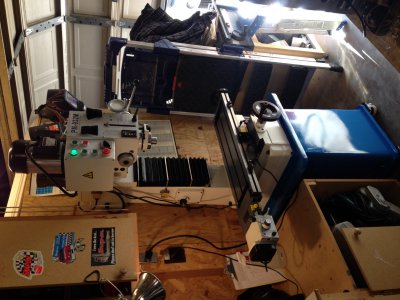

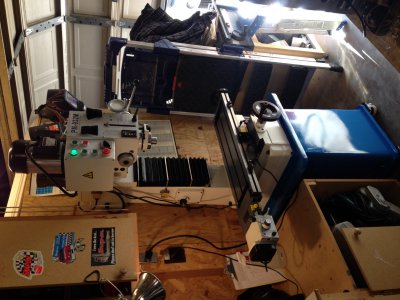

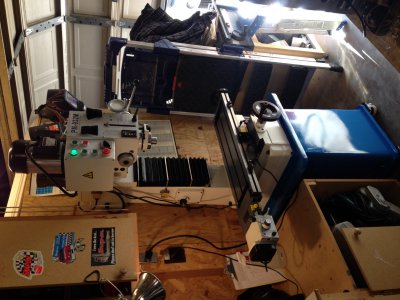

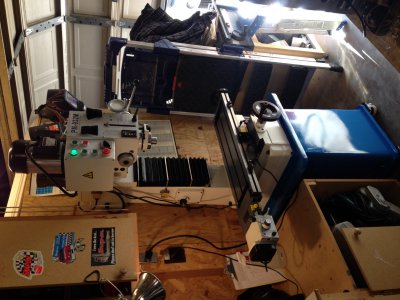

The PM932 has arrived!

- Thread starter jbolt

- Start date

- Joined

- Sep 24, 2010

- Messages

- 3,096

Yup, I'm green with envy. Did you get the PDF model or the standard model? Either one will be a real workhorse so I gues it really doesn't matter that much anyway. You shouldn't have much cleaning or prep work to do on a PM machine because they have been coming through pretty much ready to go to work when they arrive. I would make sure it is on level and stable ground and in tram and follow the start up procedure to break in all of the gears and other components as directed. Also make sure that you do follow the instructions about the initial oil change after a month to insure that all of the machining particles and junk is washed away and replaced with good high quality lube as required in the manual. Don't forget to snap a few pics as you go assembling it and don't forget that first project too. Uncrating pics are like a naked pole dancer, just cant look away till its all done...

- Joined

- Dec 3, 2013

- Messages

- 1,844

Got it cleaned up, did the break in, squared the column and trammed the head so all good to go.

Does anyone know what the torque specs are for the cokumn to base bolts are. My column was shipped with the bolts finger tight. I have torqued them to 90lbs but I can still pull on the column and get 0.002" deflection. That is with the gibs locked.

Sorry about the sideways photos.

Jay

Does anyone know what the torque specs are for the cokumn to base bolts are. My column was shipped with the bolts finger tight. I have torqued them to 90lbs but I can still pull on the column and get 0.002" deflection. That is with the gibs locked.

Sorry about the sideways photos.

Jay

- Joined

- Nov 16, 2012

- Messages

- 5,596

90 ftlb should be quite adequate if the threads were lightly oiled.

I'm a little confused on how you measured 2 thou deflection. Can you show the setup and where you were pushing? Was the head raised all the way up? In any event, push on anything hard enough or with impulse -and it will flex... The other day, I had a 4" diameter shaft of 1045, 2.5' long chucked in the lathe and supported at the tailstock. With a DI at the chuck end, all I had to do was press with one finger at the TS end, and I could see a slight deflection. The shaft still came out within a thou from one end to the other... With your machine, the real test is to mill some metal and see if it performs as it should.

Good luck.... There's getting to be a lot of 932's out there and it's a very popular machine. You done good...

Ray

I'm a little confused on how you measured 2 thou deflection. Can you show the setup and where you were pushing? Was the head raised all the way up? In any event, push on anything hard enough or with impulse -and it will flex... The other day, I had a 4" diameter shaft of 1045, 2.5' long chucked in the lathe and supported at the tailstock. With a DI at the chuck end, all I had to do was press with one finger at the TS end, and I could see a slight deflection. The shaft still came out within a thou from one end to the other... With your machine, the real test is to mill some metal and see if it performs as it should.

Good luck.... There's getting to be a lot of 932's out there and it's a very popular machine. You done good...

Ray

- Joined

- Dec 3, 2013

- Messages

- 1,844

Hi Ray,

Setup was, 0-4-0 indicator mounted in the spindle pointing forward, head down until indicator touching a 1-2-3 block, head gibs locked, quill locked. Grab top of column and pull forward. I would geustimate about 50 -60 lbs of pulling force.

Jay

Setup was, 0-4-0 indicator mounted in the spindle pointing forward, head down until indicator touching a 1-2-3 block, head gibs locked, quill locked. Grab top of column and pull forward. I would geustimate about 50 -60 lbs of pulling force.

Jay

- Joined

- Jul 7, 2012

- Messages

- 641

- Joined

- Nov 3, 2013

- Messages

- 405

Looks nice.

As to the deflection you just shouldn't expect full sized machine rigidity from a benchtop mill. Giving up a little rigidity is the price you pay for a machine 1/2-1/3rd the weight of the more rigid full sized mills.

Hey, you ain't using it for production so super heavy cuts are not required anyway.

Gotta be nice running a brand new machine!

As to the deflection you just shouldn't expect full sized machine rigidity from a benchtop mill. Giving up a little rigidity is the price you pay for a machine 1/2-1/3rd the weight of the more rigid full sized mills.

Hey, you ain't using it for production so super heavy cuts are not required anyway.

Gotta be nice running a brand new machine!