-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Pm-1440gt Has Landed

- Thread starter jbolt

- Start date

- Joined

- Dec 3, 2013

- Messages

- 1,844

Just my opinion, but I'm just a hobbyist and not looking for mil-spec finishes, so that would more that work for me. I'd be more than happy to take that thing off your hands for ya once I land somewhere.

Can't have it.

I do customer work to support my hobbies. One of the main reasons for upgrading was to expand my work envelope and be able to produce parts quicker. This lathe is definitely a huge step forward.

- Joined

- Dec 3, 2013

- Messages

- 1,844

waaahhhaaHA! I finally ran some customer parts today. What a huge difference. I parted off a bunch of 2" 6061 stock. Something I could not even think about on my old lathe. An ISCAR parting tool with a drizzle of kerosene went through it like butter. Will be even better with the VFD conversion and variable speed.

Here are some parts I have permission to post pictures of. I make a couple a dozen a year for a local shop. Their smallest manual lathe has a 24" chuck on it so they farm out this kind of stuff. Made from 3/8" 7075. The long skinny part is 0.187" dia with a tolerance of +0.0 -0.0005". The short fat end is a 0.25"bearing fit with the same tolerance. The long skinny part is about 2" long and has to be cut in a single pass. I used to scrap about 30% on my old lathe. I did these in about a third the time it used to take on my old lathe with no scrapped parts. Awesome!

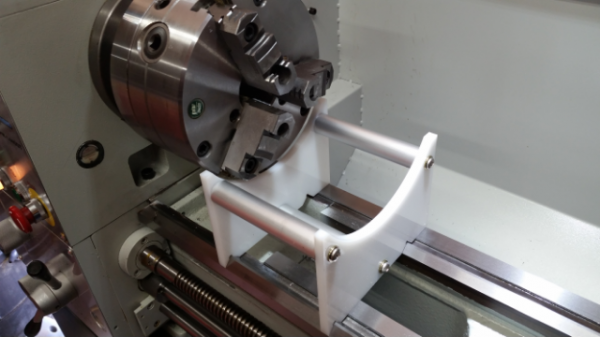

I also made up a chuck cradle. I had always meant to make one for my old lathe but never did. A must with the heavier 8" chucks. Made from 3/8" poly and 1" aluminum tube with press in star threaded inserts.

Here are some parts I have permission to post pictures of. I make a couple a dozen a year for a local shop. Their smallest manual lathe has a 24" chuck on it so they farm out this kind of stuff. Made from 3/8" 7075. The long skinny part is 0.187" dia with a tolerance of +0.0 -0.0005". The short fat end is a 0.25"bearing fit with the same tolerance. The long skinny part is about 2" long and has to be cut in a single pass. I used to scrap about 30% on my old lathe. I did these in about a third the time it used to take on my old lathe with no scrapped parts. Awesome!

I also made up a chuck cradle. I had always meant to make one for my old lathe but never did. A must with the heavier 8" chucks. Made from 3/8" poly and 1" aluminum tube with press in star threaded inserts.

- Joined

- Dec 3, 2013

- Messages

- 1,844

Love the chuck cradle. I'll have to keep that in mind for when I can no longer muscle my chucks around by hand.

I change between chucks a lot and it gets interesting supporting the 8" chucks with one arm while engaging a cam lock with the other.

- Joined

- Nov 11, 2014

- Messages

- 111

Made from 3/8" 7075. The long skinny part is 0.187" dia with a tolerance of +0.0 -0.0005". The short fat end is a 0.25"bearing fit with the same tolerance. The long skinny part is about 2" long and has to be cut in a single pass.

You finish cut that long & skinny part to that tolerance? How do you avoid flexing?

Very nice lathe, I have it's kid brother the 1340.

- Joined

- Dec 3, 2013

- Messages

- 1,844

You finish cut that long & skinny part to that tolerance? How do you avoid flexing?

That is why it has to be done in a single pass. I use these CCGT 32.51 carbide inserts and kerosene for cutting fluid. The 80 deg inserts with the small tip radius at that DOC will cut without pushing or pulling the material. The 7075 also helps. When I first started making these a few years ago it took a while to get the process down, especially on my previous lathe which was less precise, less rigid and not the same quality of bearings. On my old lathe I would have to run the spindle for a hour or more to get it thermally stable and then run all the parts. My 1440GT has a spindle run out of less than 0.0001" when cold which I think is quite impressive.

Last edited:

- Joined

- Mar 1, 2015

- Messages

- 71

Looks Nice Hopefully you will have it up and running in short orderWell 6-1/2 months later it has finally arrived. It was supposed to have been delivered yesterday but UPS messed about and didn't deliver until today. They gave me a 4 hour window today and showed up 45 minutes late.

PM put the factory crate on another pallet so it sits really high. I had to cut away the middle section of the pallet and crate to get my engine lift under it. Between an engine lift, a floor jack and a toe jack it took me, my wife and daughter about 2 hours to get it undone and in place in the garage. I got the leveling feet on after chasing the 1/2-12 whitworth with a 1/2-13 tap.

Here is a quick picture. The back guard is still off from the move. I will put that back on after I get it cleaned up and the DRO on.

More to come.....

View attachment 135507