- Joined

- Dec 8, 2013

- Messages

- 2,651

Re: Code issue, please help. This stopped being fun a few days ago.

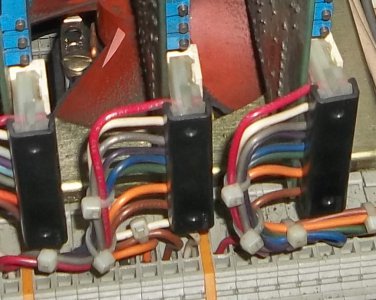

Yes. The orange paint is glue intended to hold them as they were set at the factory. Those ones are probably not intended for field adjustment. There are also six pots on the top edge of the board.

Would the two "blue squares with orange paint" near the white label on the bottom left, be the pots? They look like a pot to me.

Pierre

Yes. The orange paint is glue intended to hold them as they were set at the factory. Those ones are probably not intended for field adjustment. There are also six pots on the top edge of the board.