B

BRIAN

Forum Guest

Register Today

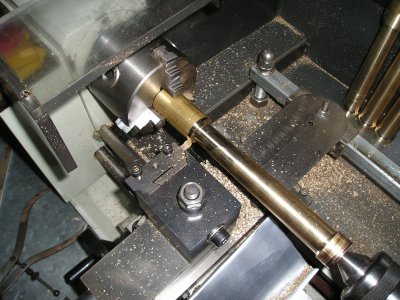

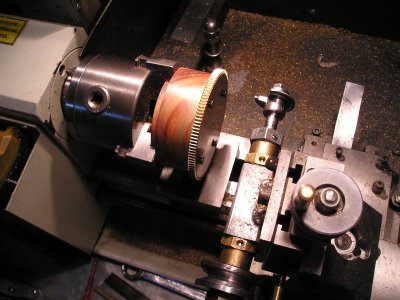

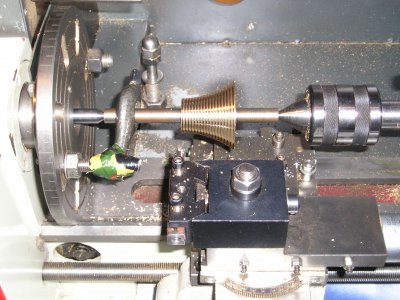

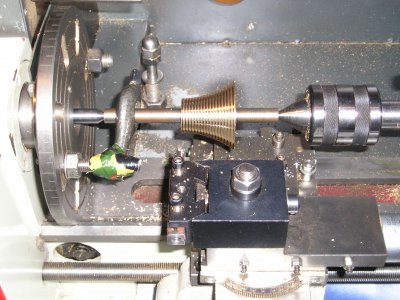

hI ITS MY FIRST TRY AT A POST BUT YOU MAT LIKE TO SEE MY FIRST WORK ON MY MINI LATHE. IWANTED TO START THIS CLOCK 30 YEARS AGO BUT THINGS KEPT GETTING IN THE WAY. WHEN I STARTED THIS TIME A FRIEND ASKED ME TO MAKE ONE FOR HER SO 2 IS NOT A LOT HARDER THAN 1 WHEN YOU HAVE IT SET UP SO OFF WE GO!!! IF THIS WORKS I WILL POST PART2. REGARDS BRIAN

Last edited by a moderator: