-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tangential Radiusing Tool for the Lathe

- Thread starter Jim2

- Start date

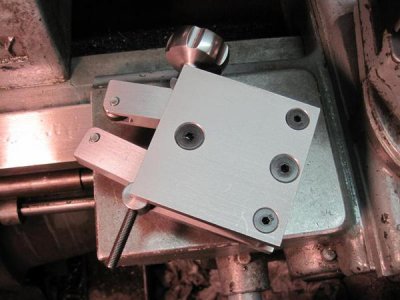

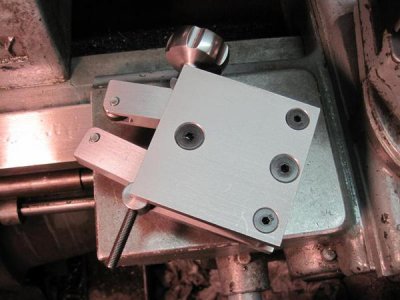

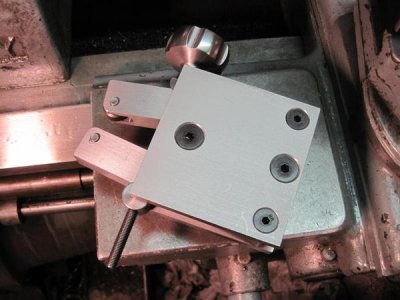

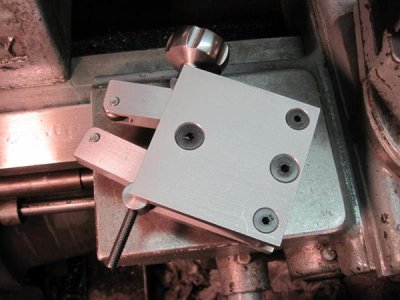

If you look closely there's a hole that is used to remove the material around the "back" corner. Removing the metal in the other corners was done with a small end mill on the one and a slitting saw on the other. Both were done from the same set up. The toolbit is 3/8" x 3/8", and this is a CXA tool holder. This pic shows it the best:

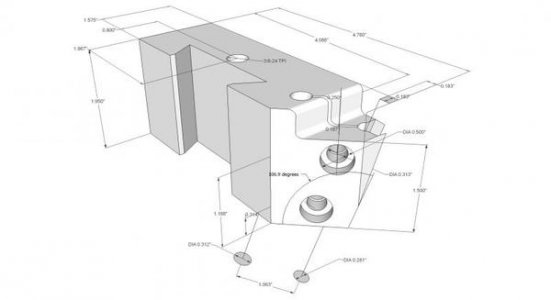

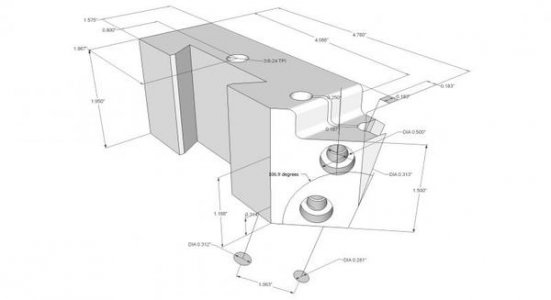

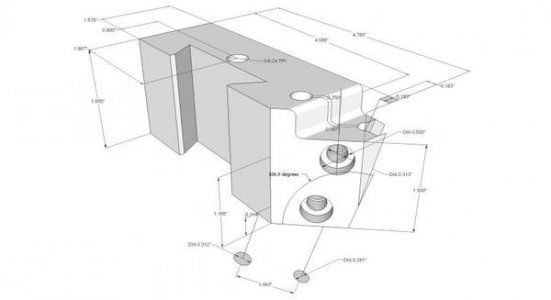

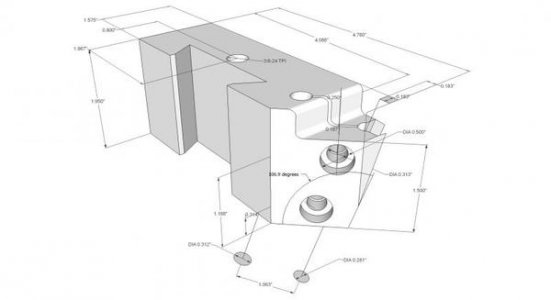

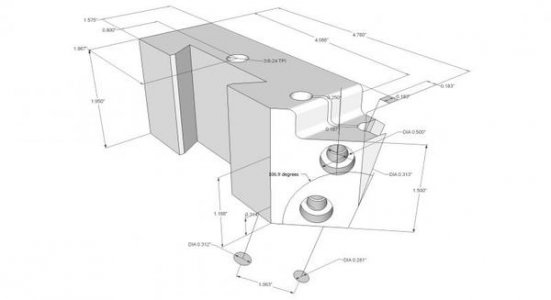

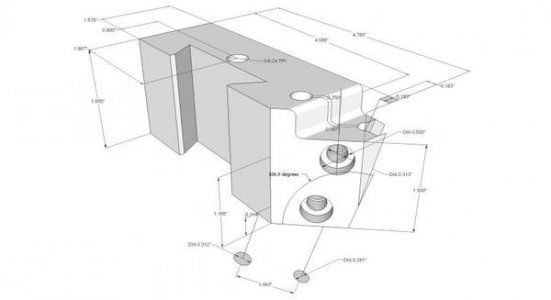

Here's the drawing. . . .

Jim

Here's the drawing. . . .

Jim

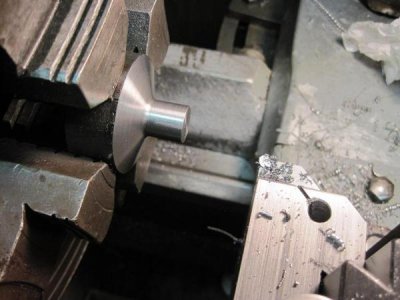

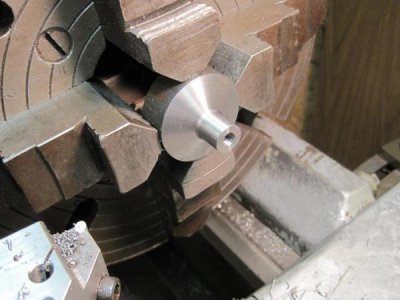

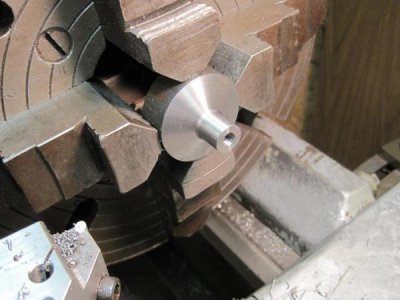

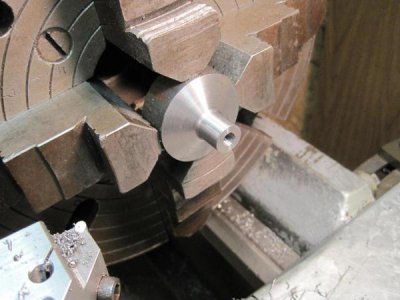

Used the tool to make a knob yesterday. I don't have a finished pic, but here's a couple of in-process pics. . . .

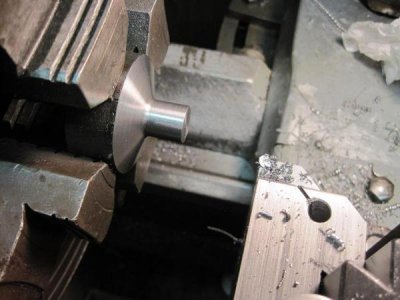

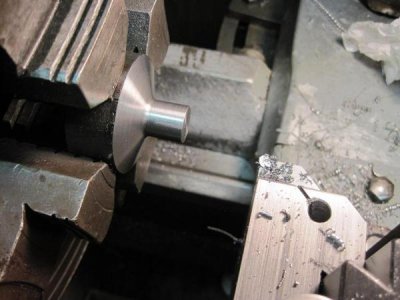

Here's the radiusing tool in the cut:

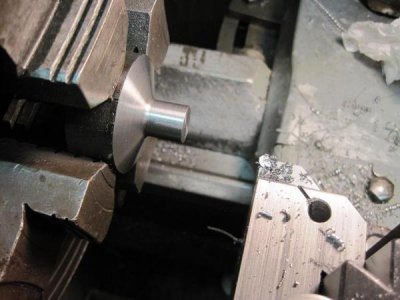

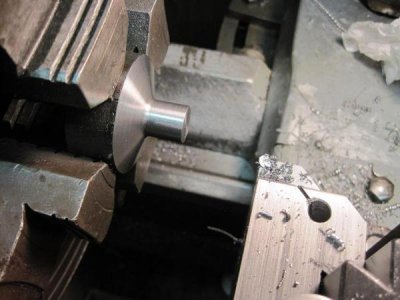

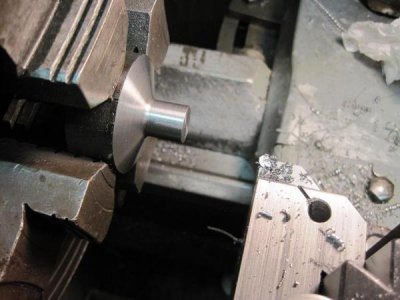

Radiusing finished:

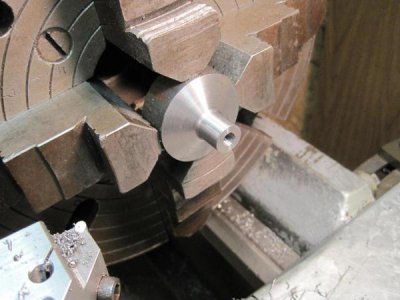

Bottom finished:

Rounding off the gripping portion:

Using a ball-nose end-mill to clean up the rough-cut "dimples".

Hollowing it out for some weight reduction:

Jim

Here's the radiusing tool in the cut:

Radiusing finished:

Bottom finished:

Rounding off the gripping portion:

Using a ball-nose end-mill to clean up the rough-cut "dimples".

Hollowing it out for some weight reduction:

Jim

- Joined

- Sep 28, 2013

- Messages

- 4,319

way cool! I love the weight reduction efforts for a knob going on a knurler going onto what looks like a very heavy lathe  That's the kind of obsessive attention to detail I love!

That's the kind of obsessive attention to detail I love!

- Joined

- Nov 4, 2012

- Messages

- 52

Jim:

I heard you were still on the forum so I looked you up and I found your article here on your building of a Tangential Lathe Tool.

I was fortunate when starting to think about starting into the amateur machinist hobby to learn from Rudy Kouhoupt about the Diamond Tool Holder. I bought the Left and Right hand versions. I do think for my limited experience they exceed any insert style tooling I also have as part of the starter package I bought from Little Machine Shop Lathe and Mill. I enjoy using a tool which has more than brute force behind its concept.

The Tangential tool design leverages many tool cutting concepts behind its seemingly simple design. Which is why I am currently working with a few others on the hobby machinist forum to design a Flywheel based Tangential Tool Holder Fly Cutter for the Mini-Mill. I believe it will complement your efforts here and on the other build of yours for a Tangential Fly Cutter.

My initial thoughts are as follows:

1. Nominal 6 inch Radius

2. Nominal 1 to a maximum 2 inch thick

3. The Tool bit to be either 1/4 round or square stock

4. The clamp would comprise a circle with an interior nominal 1/4 inch square, per the advice from Gary at Eccentric Engineering as he states the square clamp provides a better clamp on both the round and square tool bit stock

5. My idea of the round clamp in the Flywheel is so the square tool stock may be rotated for optimal cutting on the flat or any desired angle of cut the amateur machinist may want to make

6. by having the round clamp inside the Flywheel the Flywheel can have the required Optimal Tangential tool angle drilled in the Flywheel mass and leave sufficient material to clamp down the interior round clamp which actually holds the Tool stock.

I am sure looking at you tool design approach you have practical wisdom you can bring to the table for this proposal.

Thanks for Listing to a old man struggling to learn a new hobby.

I heard you were still on the forum so I looked you up and I found your article here on your building of a Tangential Lathe Tool.

I was fortunate when starting to think about starting into the amateur machinist hobby to learn from Rudy Kouhoupt about the Diamond Tool Holder. I bought the Left and Right hand versions. I do think for my limited experience they exceed any insert style tooling I also have as part of the starter package I bought from Little Machine Shop Lathe and Mill. I enjoy using a tool which has more than brute force behind its concept.

The Tangential tool design leverages many tool cutting concepts behind its seemingly simple design. Which is why I am currently working with a few others on the hobby machinist forum to design a Flywheel based Tangential Tool Holder Fly Cutter for the Mini-Mill. I believe it will complement your efforts here and on the other build of yours for a Tangential Fly Cutter.

My initial thoughts are as follows:

1. Nominal 6 inch Radius

2. Nominal 1 to a maximum 2 inch thick

3. The Tool bit to be either 1/4 round or square stock

4. The clamp would comprise a circle with an interior nominal 1/4 inch square, per the advice from Gary at Eccentric Engineering as he states the square clamp provides a better clamp on both the round and square tool bit stock

5. My idea of the round clamp in the Flywheel is so the square tool stock may be rotated for optimal cutting on the flat or any desired angle of cut the amateur machinist may want to make

6. by having the round clamp inside the Flywheel the Flywheel can have the required Optimal Tangential tool angle drilled in the Flywheel mass and leave sufficient material to clamp down the interior round clamp which actually holds the Tool stock.

I am sure looking at you tool design approach you have practical wisdom you can bring to the table for this proposal.

Thanks for Listing to a old man struggling to learn a new hobby.