-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Taking the CNC Plunge

- Thread starter TomS

- Start date

Thanks Steve. I didn't think you could solder two wires to one terminal. Ill give it a try tomorrow.

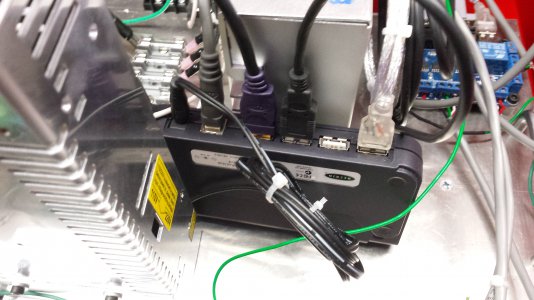

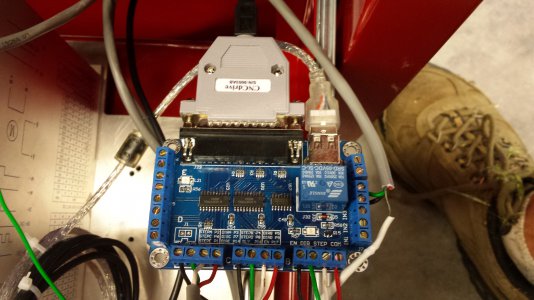

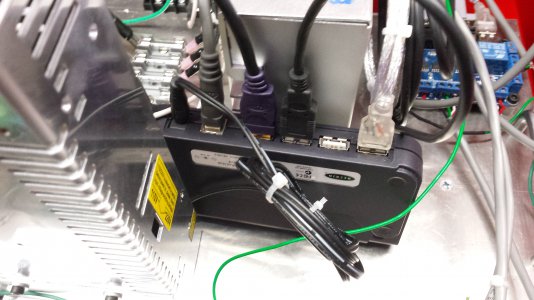

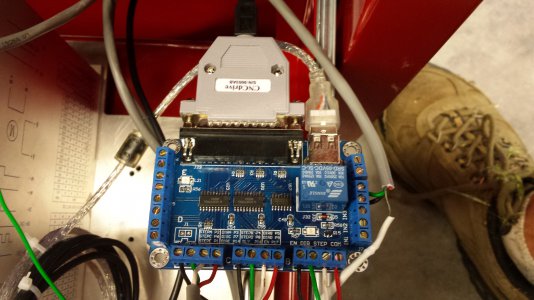

I was going to attach a couple of shots of the X and Y axis and limit switches wired to the breakout board. I also have the UC-100 and the Bob wired to the USB hub but the pictures I took aren't very good. I'll take more tomorrow.

Tom S

I was going to attach a couple of shots of the X and Y axis and limit switches wired to the breakout board. I also have the UC-100 and the Bob wired to the USB hub but the pictures I took aren't very good. I'll take more tomorrow.

Tom S

Tom, I soldered a short pigtail to each (+) pin on the connector and then twisted and soldered them together with the single wire to the BOB. Shrink wrap and zip tie to protect the bare ends.

Jay

Good idea! I tried soldering two wires to one of the plug pins and it didn't work very well. I melted the plastic piece that separates the pins. Could be because I'm using 18 gauge wire and the pins take something smaller, like 20 or 22 gauge. Tomorrow I need to find another plug and some smaller gauge wire.

Tom S

Got the Z axis wired to the BoB today. With that out of the way I believe I'm ready to test the motors. I've got 220v power to the power supplies through the SSR with the circuit protected with 4A slow blow fuses. The drivers are wired to the power supplies. The driver dip switches are set. The BoB is wired to the drivers and connected to the USB hub for 5v power. The UC-100 is also connected to the USB hub and the hub is connected to my laptop. Still have to install the UC-100 software. Cooling fans are working. Limit/home switches are mounted and wired to the BoB. Limit stops will be set once the motors are tested. Mach 3 is loaded and the configuration file is installed.

Have I overlooked anything? I don't want to smoke anything on start up. Any tests I should run before powering up? What tests should I run to verify that the system is responding correctly?

Here's a few pics of my electronics wiring. I still have to tidy it up a bit.

Tom S

Have I overlooked anything? I don't want to smoke anything on start up. Any tests I should run before powering up? What tests should I run to verify that the system is responding correctly?

Here's a few pics of my electronics wiring. I still have to tidy it up a bit.

Tom S

- Joined

- Dec 3, 2013

- Messages

- 1,844

I've got 220v power to the power supplies through the SSR with the circuit protected with 4A slow blow fuses.

It looks like you have 110v through the SSR, your post says 220v? What are your power supplies set to? 110v or 220v?

Where is the 110v supply into the SSR coming from and what size breaker is it on?

If you are concerned about powering up I would disconnect the drives from the power supplies and remove all but one fuse. Power up each PS one at a time and check the output voltage. Then hookup and test one drive & motor at a time.

Jay

It looks like you have 110v through the SSR, your post says 220v? What are your power supplies set to? 110v or 220v?

Where is the 110v supply into the SSR coming from and what size breaker is it on?

If you are concerned about powering up I would disconnect the drives from the power supplies and remove all but one fuse. Power up each PS one at a time and check the output voltage. Then hookup and test one drive & motor at a time.

Jay

Jay - Thanks for your questions and input. I have two power feeds into the electronics enclosure. The junction block next to the fuse holder and SSR is fed with 220v. The other junction block next to the X axis power supply is fed with 110v. I've set the X and Y axis power supplies to 220v. The Z axis PS is voltage sensing so there is no manual setting. The black wire is the 220v "Line/Load" feeding the SSR. 220v out of the SSR is feeding the fuse block. The "neutral" in is feeding the junction block. The terminals on the other side of the SSR are being fed with 5v DC. Each power supply is protected with a 4A slow blow fuse. Hope this is clear and not confusing.

Tom S

- Joined

- Dec 3, 2013

- Messages

- 1,844

Jay - Thanks for your questions and input. I have two power feeds into the electronics enclosure. The junction block next to the fuse holder and SSR is fed with 220v. The other junction block next to the X axis power supply is fed with 110v. I've set the X and Y axis power supplies to 220v. The Z axis PS is voltage sensing so there is no manual setting. The black wire is the 220v "Line/Load" feeding the SSR. 220v out of the SSR is feeding the fuse block. The "neutral" in is feeding the junction block. The terminals on the other side of the SSR are being fed with 5v DC. Each power supply is protected with a 4A slow blow fuse. Hope this is clear and not confusing.

Tom S

So if I understand you correctly, the black, white & green three-wire coming into the SSR, terminal block and ground lug are (black = 110v, white = 110v and green = ground) and you are switching one leg of the 220v circuit?

Jay

So if I understand you correctly, the black, white & green three-wire coming into the SSR, terminal block and ground lug are (black = 110v, white = 110v and green = ground) and you are switching one leg of the 220v circuit?

Jay

No, I have two separate power feeds into the enclosure: one 220v and one 110v circuits. The black, white and green wires coming into the SSR, terminal block and ground lug is 220v. I measured the power across the SSR when I powered up the 5v DC transformer and I get 220V at the SSR. The load side is protected by the fuse block (one 4A fuse per power supply) and the neutral side are the white wires going to each of the power supplies. And the green is grounded at the lug. 110v power comes into the other junction block (next to the X axis power supply). This circuit feeds the fans, the 5v DC transformer for the BoB power and SSR control signal, and the computer.

Sorry if I'm not being clear. I'm electrically challenged and may be using terms and phrases that don't accurately describe what I've done.

Tom S

- Joined

- Dec 3, 2013

- Messages

- 1,844

No worries. I'm pretty straight with standard residential wiring having been a general contractor for the past 25 years but I am also less comfortable with electronics or high voltage wiring.

Sorry if I am presenting what you may already know but I want to make sure we are on the same page.

Standard residential wiring is the US is typically as follows:

Three wires into the main service from the Utility company: Line 1 (110v), Line 2 (110v), Ground

Typical home circuit.

110vac (black wire = Line 1 (hot), (white wire = neutral) ( green or bare wire = ground). 110v is measured across the hot and neutral.

220v (3-wire), (black wire = Line 1 (hot), (Red wire = Line 2 (hot) ( green or bare wire = ground). 220v is measured across Line 1 & Line 2, or 110v from line 1 or 2 to ground.

220v (4-wire), (black wire = Line 1 (hot), (Red wire = Line 2 (hot) (white wire = neutral) ( green or bare wire = ground)

Where I am getting confused is when you say you have 220v to the SSR on a single wire? On your power supplies, for 220v, terminals L & N would connect to Line 1 and Line 2 . There would be no neutral, just ground.

Jay

Sorry if I am presenting what you may already know but I want to make sure we are on the same page.

Standard residential wiring is the US is typically as follows:

Three wires into the main service from the Utility company: Line 1 (110v), Line 2 (110v), Ground

Typical home circuit.

110vac (black wire = Line 1 (hot), (white wire = neutral) ( green or bare wire = ground). 110v is measured across the hot and neutral.

220v (3-wire), (black wire = Line 1 (hot), (Red wire = Line 2 (hot) ( green or bare wire = ground). 220v is measured across Line 1 & Line 2, or 110v from line 1 or 2 to ground.

220v (4-wire), (black wire = Line 1 (hot), (Red wire = Line 2 (hot) (white wire = neutral) ( green or bare wire = ground)

Where I am getting confused is when you say you have 220v to the SSR on a single wire? On your power supplies, for 220v, terminals L & N would connect to Line 1 and Line 2 . There would be no neutral, just ground.

Jay