My Monarch 12CK has a rattle inside the clutch someplace and I am trying to pull it apart to find the rattle and fix it.

I have gotten the floating plate off, but cannot get the "driving plate", AKA clutch plate, to come out. This is the plate that actually has the frictions on it. From all I can see, the plate is free-floating inside the clutch disk sheave, AKA 3 belt pulley, and is driven by two keys on the outer edge. I can see that the driving plate has worn into the keys over time, in the forward direction, and have rotated the driving plate backwards so that the wear knotches won't keep it from coming out. There is nowhere to pry on it really, except the small gaps by the keys, and no puller holes where I could put a bolt in to pull by.

I have repeatedly tried to pull the hub and back plate out, which would pull the clutch plate out with it, if the clutch plate would come out.

I do not want to get crazy with my methods because Edgemont clutch parts are probably pretty hard to come by.

Looking for ideas.

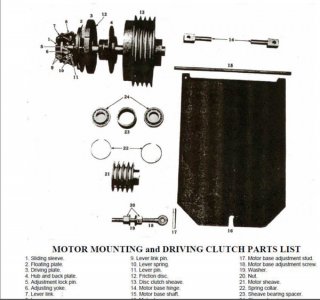

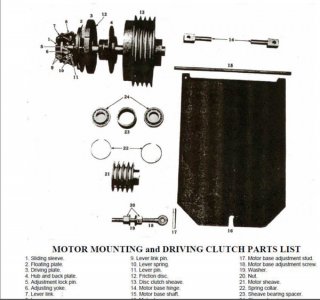

Pics attached. See diagram to match parts names to my text. Number 3 is what won't come out, but moves about 1/16" inside number 13. Number 4 wants to come out, but is held in by number 3.

Thanks,

Chris

I have gotten the floating plate off, but cannot get the "driving plate", AKA clutch plate, to come out. This is the plate that actually has the frictions on it. From all I can see, the plate is free-floating inside the clutch disk sheave, AKA 3 belt pulley, and is driven by two keys on the outer edge. I can see that the driving plate has worn into the keys over time, in the forward direction, and have rotated the driving plate backwards so that the wear knotches won't keep it from coming out. There is nowhere to pry on it really, except the small gaps by the keys, and no puller holes where I could put a bolt in to pull by.

I have repeatedly tried to pull the hub and back plate out, which would pull the clutch plate out with it, if the clutch plate would come out.

I do not want to get crazy with my methods because Edgemont clutch parts are probably pretty hard to come by.

Looking for ideas.

Pics attached. See diagram to match parts names to my text. Number 3 is what won't come out, but moves about 1/16" inside number 13. Number 4 wants to come out, but is held in by number 3.

Thanks,

Chris