- Joined

- Mar 25, 2013

- Messages

- 5,131

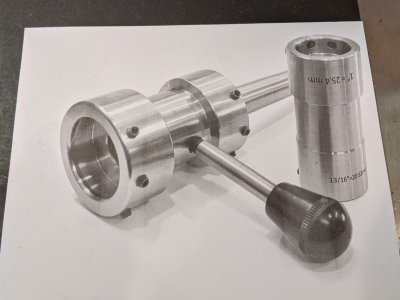

It's about time I got around to making this. After looking over a few designs, I decided to emulate this:

I had a piece of 1" 1144 on the shelf that I thought would make a good MT2 taper shaft.

I set my compound against a known good MT2 taper held between centers. Then I cut the taper holding the stock between centers.

The straight part is turned to 0.749. I will ream the holder to 0.750.

The holder was made from 12L14:

It slides perfectly. I still need to put in a set screw to hold the die and add a lever handle. I plan to make this reversible so I can have a 1" die on one end and a 13/16" on the other.

Any comments on handle length? Should it clear the lathe bed or purposefully interfere with it?

Robert

I had a piece of 1" 1144 on the shelf that I thought would make a good MT2 taper shaft.

I set my compound against a known good MT2 taper held between centers. Then I cut the taper holding the stock between centers.

The straight part is turned to 0.749. I will ream the holder to 0.750.

The holder was made from 12L14:

It slides perfectly. I still need to put in a set screw to hold the die and add a lever handle. I plan to make this reversible so I can have a 1" die on one end and a 13/16" on the other.

Any comments on handle length? Should it clear the lathe bed or purposefully interfere with it?

Robert