- Joined

- Aug 15, 2013

- Messages

- 2,112

I have had it apart many times now and have not seen any "binders". I did use the hone lase night and it is much better, but not acting as a precision tool by any means. I was very sparing with the master cylinder hone and kept it moving at ll times.

brian

The "binders" are operated by the locking handle on top of the tailstock. Grizzly may call that part something else, but if your quill lock works, they are there. Without them you wouldn't be able to lock the quill down.

When you had it apart, did you take the quill lock and leadscrew out to see if the quill would slide freely by hand? Don't unscrew the quill locking handle all the way or you could leave the binder behind in the tailstock body. Just pull it straight up after you remove the quill and the binder should come out with it.

If you have already done all that and I'm preaching to the choir, ignore me and go back to regular programming.

Tom

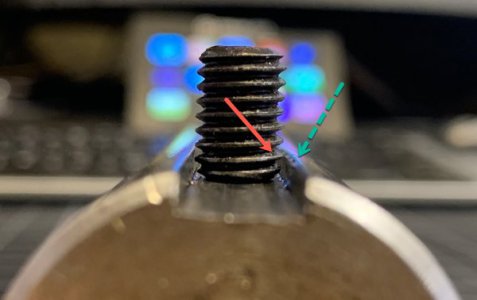

ETA: I forgot to mention, when testing the quill to bore fit, also remove the set screw that keeps the quill from twisting in the bore.

Last edited: