I don't remember where I saw a picture of this idea ( it was somewhere on the internet. For all I know , it could have been on here  ) but it looked like a good one to solve my problems with drilling a precision depth easily on the lathe, So I fabricated this up from memory. It works really well. No print .... a picture is worth a thousand words.

) but it looked like a good one to solve my problems with drilling a precision depth easily on the lathe, So I fabricated this up from memory. It works really well. No print .... a picture is worth a thousand words.

This is the complete assembly

This is the complete assembly

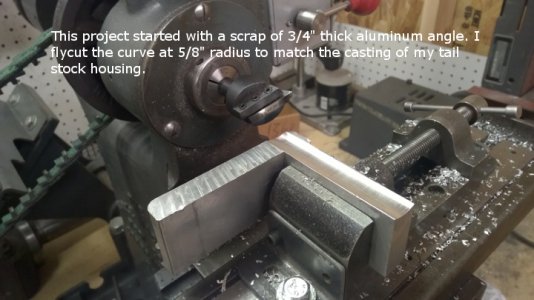

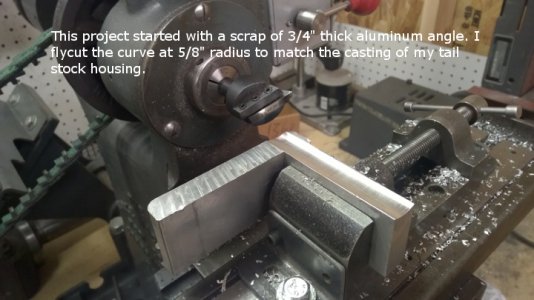

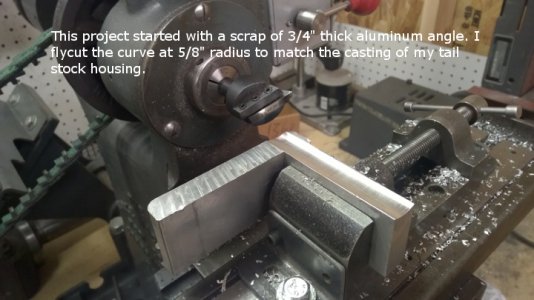

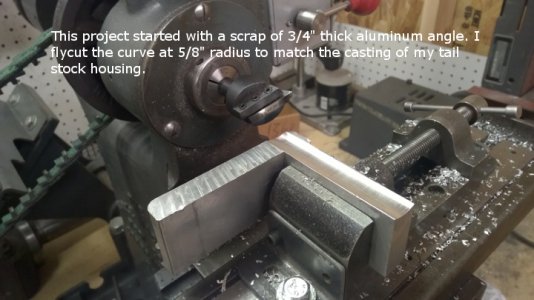

These two photos show cutting the curve to fit the tail stock and cutting to size.

These two photos show cutting the curve to fit the tail stock and cutting to size.

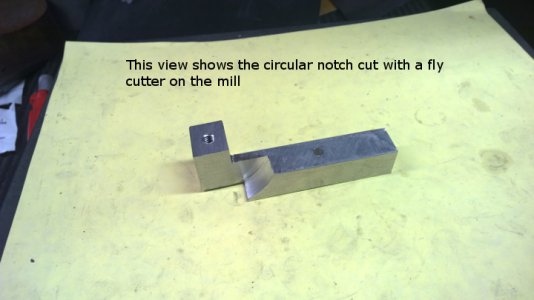

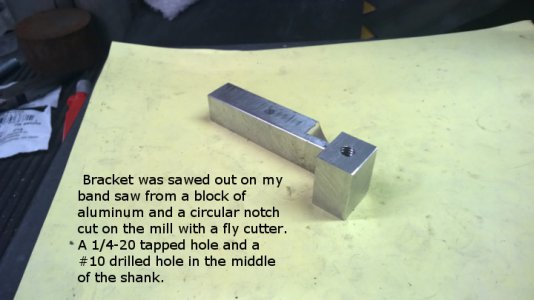

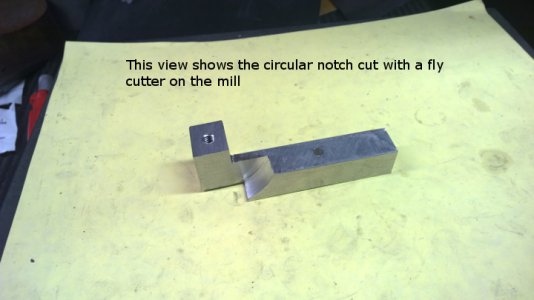

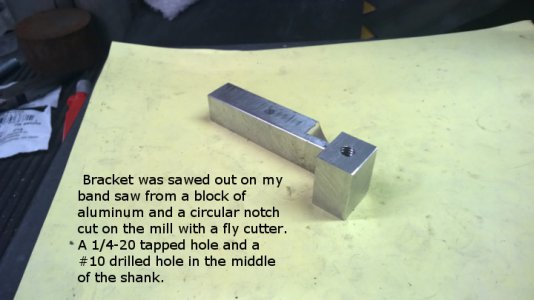

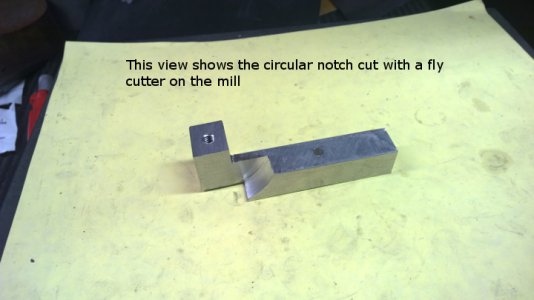

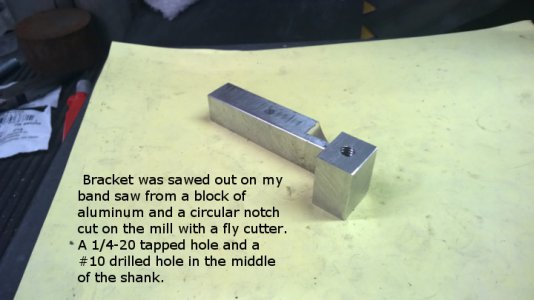

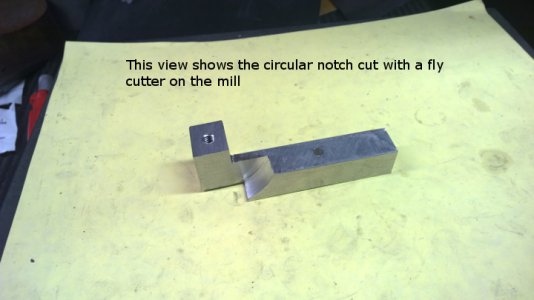

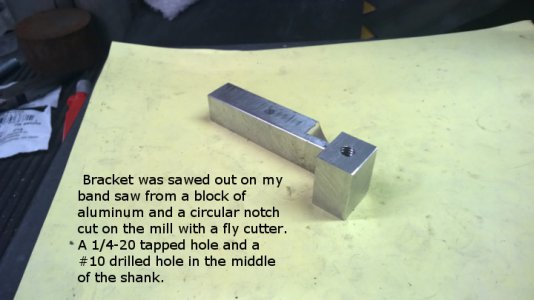

This is the finished block.

This is the finished block.

Mounted on the lathe with an indicator. I tapped the oil hole on top of the tail stock to 10-24 since it was the right size. I intend to drill a hole through the screw so I can still oil the tail stock screw.

Mounted on the lathe with an indicator. I tapped the oil hole on top of the tail stock to 10-24 since it was the right size. I intend to drill a hole through the screw so I can still oil the tail stock screw.

I made this piece for the front from 1/4" aluminum plate.

I made this piece for the front from 1/4" aluminum plate.

I got the indicator tip from one of those $3 indicator point kits and used the longest one. I turned the groove in the end to go in the slot in the aluminum plate that clamps to the tail stock spindle. The tail stock pulls the indicator and shows exactly how far it has moved. The spring tension in the indicator pulls the indicator back automatically and keeps it tight against the plate thus reading accurately in both directions.

I got the indicator tip from one of those $3 indicator point kits and used the longest one. I turned the groove in the end to go in the slot in the aluminum plate that clamps to the tail stock spindle. The tail stock pulls the indicator and shows exactly how far it has moved. The spring tension in the indicator pulls the indicator back automatically and keeps it tight against the plate thus reading accurately in both directions.

Mark Frazier

) but it looked like a good one to solve my problems with drilling a precision depth easily on the lathe, So I fabricated this up from memory. It works really well. No print .... a picture is worth a thousand words.

) but it looked like a good one to solve my problems with drilling a precision depth easily on the lathe, So I fabricated this up from memory. It works really well. No print .... a picture is worth a thousand words. This is the complete assembly

This is the complete assembly

These two photos show cutting the curve to fit the tail stock and cutting to size.

These two photos show cutting the curve to fit the tail stock and cutting to size.

This is the finished block.

This is the finished block. Mounted on the lathe with an indicator. I tapped the oil hole on top of the tail stock to 10-24 since it was the right size. I intend to drill a hole through the screw so I can still oil the tail stock screw.

Mounted on the lathe with an indicator. I tapped the oil hole on top of the tail stock to 10-24 since it was the right size. I intend to drill a hole through the screw so I can still oil the tail stock screw. I made this piece for the front from 1/4" aluminum plate.

I made this piece for the front from 1/4" aluminum plate. I got the indicator tip from one of those $3 indicator point kits and used the longest one. I turned the groove in the end to go in the slot in the aluminum plate that clamps to the tail stock spindle. The tail stock pulls the indicator and shows exactly how far it has moved. The spring tension in the indicator pulls the indicator back automatically and keeps it tight against the plate thus reading accurately in both directions.

I got the indicator tip from one of those $3 indicator point kits and used the longest one. I turned the groove in the end to go in the slot in the aluminum plate that clamps to the tail stock spindle. The tail stock pulls the indicator and shows exactly how far it has moved. The spring tension in the indicator pulls the indicator back automatically and keeps it tight against the plate thus reading accurately in both directions.Mark Frazier