I was trying to re-mount my t-bar cut-off tool and could not get the threads to bite. It had seemed fine when I last removed it. I found that T nut was stripped and the 10-32 bolt was also buggered.

Saturday night and the last Mom & Pop in town was closed for the weekend. I went to both our big boxes (farm supply and home improvement.) Neither had SHCS in 10-32 (only 10-24) and their longest was only 1 and a 1/2 inches. (The special tool post for the cut off tool requires a 2 & 1/4 and I could not find anywhere else on the Taig that uses that size.)

I was able to find a zinc/steel machine screw in 10-32 but my choices were 2 inches or 3 inches.

I threaded the t-nut onto the 3 inch screw, only enough to allow 1 bite of the thread showing through, then took up all the slack with the nut, holding the machine screw with a screwdriver to keep it from threading into the t-nut and possibly scoring the floor of the slot on the cross slide. Worked just fine!

Photo attached.

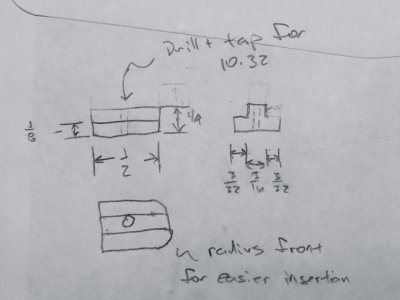

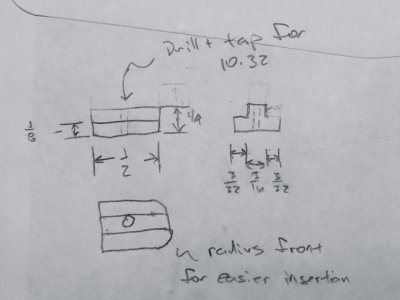

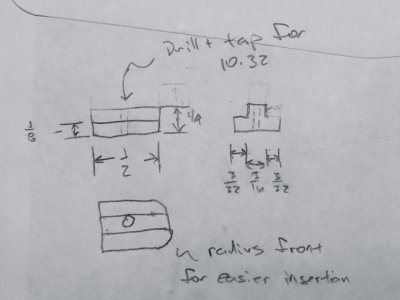

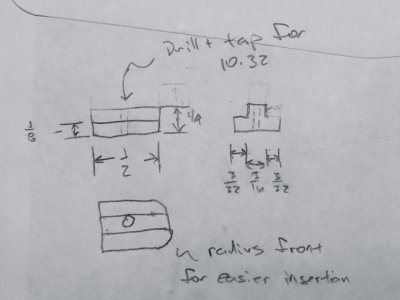

I am considering making some beefier t-nuts - especially for the cut off tool, since I have to crank it pretty hard to keep it form moving. Here is my sketch on the back of an envelope.

Since I am brand new to machining and my Taig is only a week old, I was wondering if there are other parts likely to break after Mom & Pop close. Any suggestions for an emergency kit? (for steel, not for skin!)

Thanks.

KH

Saturday night and the last Mom & Pop in town was closed for the weekend. I went to both our big boxes (farm supply and home improvement.) Neither had SHCS in 10-32 (only 10-24) and their longest was only 1 and a 1/2 inches. (The special tool post for the cut off tool requires a 2 & 1/4 and I could not find anywhere else on the Taig that uses that size.)

I was able to find a zinc/steel machine screw in 10-32 but my choices were 2 inches or 3 inches.

I threaded the t-nut onto the 3 inch screw, only enough to allow 1 bite of the thread showing through, then took up all the slack with the nut, holding the machine screw with a screwdriver to keep it from threading into the t-nut and possibly scoring the floor of the slot on the cross slide. Worked just fine!

Photo attached.

I am considering making some beefier t-nuts - especially for the cut off tool, since I have to crank it pretty hard to keep it form moving. Here is my sketch on the back of an envelope.

Since I am brand new to machining and my Taig is only a week old, I was wondering if there are other parts likely to break after Mom & Pop close. Any suggestions for an emergency kit? (for steel, not for skin!)

Thanks.

KH