- Joined

- Jun 29, 2014

- Messages

- 4,058

I have the Taig lathe and milling attachment, purchased many moons ago...

Recently acquired a slick little Sherline mill, making my milling attachment somewhat obsolete.

Recently have some project where turning a taper would be desirable, e.g. boring head for my sherline mill, but I would like to do this with a compound slide, not having to setup the tailstock.

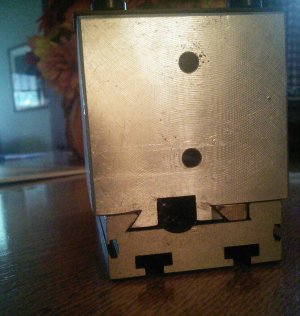

I was thinking about modifying my milling attachment in order to turn it into a compound slide.

Questions:

1) Has anybody done this successfully? If so, is it worth the trouble and did you regret it? I.e., you realized you needed the milling attachment at a later date and you should have spent the $45+shipping for the compound slide?

2) Does anybody have dimensions or a 3d model of the compound slide that I could pick dimensions from(preferably Solidworks?)

Any other words of wisdom aside from...stop being a cheap SOB!?

Thanks for your input !!

Recently acquired a slick little Sherline mill, making my milling attachment somewhat obsolete.

Recently have some project where turning a taper would be desirable, e.g. boring head for my sherline mill, but I would like to do this with a compound slide, not having to setup the tailstock.

I was thinking about modifying my milling attachment in order to turn it into a compound slide.

Questions:

1) Has anybody done this successfully? If so, is it worth the trouble and did you regret it? I.e., you realized you needed the milling attachment at a later date and you should have spent the $45+shipping for the compound slide?

2) Does anybody have dimensions or a 3d model of the compound slide that I could pick dimensions from(preferably Solidworks?)

Any other words of wisdom aside from...stop being a cheap SOB!?

Thanks for your input !!